As someone who has worked with FDM 3D printers for years—both for functional prototyping and end-use parts—ABS (Acrylonitrile Butadiene Styrene) has always been one of my most frequently used materials. Its toughness, heat resistance, and mechanical strength make it hard to replace when durability really matters.

But very early on, I learned an important lesson the hard way: ABS is not something you should ever print without proper ventilation.

The first time I printed ABS in an unventilated room, the sharp, plastic-like odor was impossible to ignore. That experience led me to a deeper question—is the smell just unpleasant, or is it actually dangerous? After reviewing research from occupational safety organizations and adjusting my own setup, the answer became crystal clear.

Yes, ABS absolutely needs to be vented—and not just for comfort, but for real health and safety reasons.

Below, I’ll walk through the science, the risks, and the exact ventilation strategies I now consider mandatory whenever I print ABS.

Why ABS Fumes Are a Real Safety Issue (The Science Explained)

When I started digging into why ABS smells so strong, I discovered that it all comes down to what happens chemically when the filament is heated to printing temperatures (typically 220–260°C).

According to research referenced by the U.S. Environmental Protection Agency (EPA), heating certain plastics releases volatile organic compounds (VOCs) and ultrafine particles (UFPs) into the air

→ https://www.epa.gov/indoor-air-quality-iaq/volatile-organic-compounds-impact-indoor-air-quality

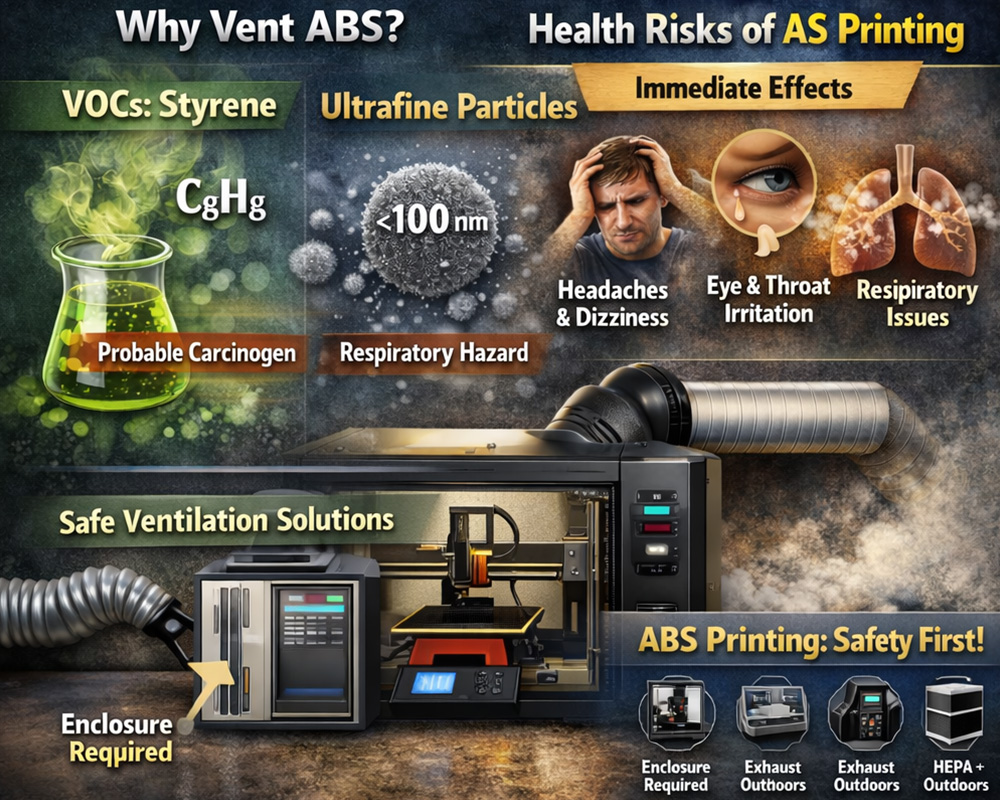

1. Volatile Organic Compounds (VOCs)

ABS is made from three monomers: acrylonitrile, butadiene, and styrene. When ABS is melted, styrene is released into the air.

Styrene is what causes that strong, unmistakable ABS smell.

The U.S. Centers for Disease Control and Prevention (CDC) notes that styrene exposure can cause:

- Eye, nose, and throat irritation

- Headaches and fatigue

- Central nervous system effects at higher concentrations

CDC Styrene Overview:

→ https://www.cdc.gov/niosh/topics/styrene/

The International Agency for Research on Cancer (IARC) classifies styrene as “probably carcinogenic to humans (Group 2A)”

→ https://monographs.iarc.who.int/list-of-classifications

That alone convinced me that venting ABS is not optional.

2. Ultrafine Particles (UFPs)

What worried me even more were ultrafine particles—particles smaller than 100 nanometers.

Studies conducted by the National Institute for Occupational Safety and Health (NIOSH) show that FDM printers emit large quantities of UFPs, especially when printing ABS

→ https://www.cdc.gov/niosh/docs/2013-101/

Because of their size, UFPs:

- Penetrate deep into the lungs

- Can cross into the bloodstream

- Bypass many of the body’s natural defenses

These particles are invisible, odorless, and far more dangerous than most people realize.

Health Risks I Take Seriously When Printing ABS

Short-Term Effects I’ve Personally Noticed

Before upgrading my ventilation:

- Headaches after long prints

- Eye and throat irritation

- Fatigue and difficulty focusing

These align closely with what OSHA lists as common VOC exposure symptoms

→ https://www.osha.gov/chemical-hazards

Long-Term Concerns

While long-term studies on hobby-level 3D printing are still developing, professional guidelines treat styrene exposure seriously. In industrial environments, engineering controls and air monitoring are mandatory.

That tells me everything I need to know:

If industry doesn’t treat ABS fumes casually, neither should I.

How I Vent ABS Safely (My Recommended Setup)

The Gold Standard: Enclosure + Active Exhaust

This is the setup I now use every single time.

1. Fully Enclosed Printer

The enclosure serves two purposes:

- Print quality: ABS warps less in a warm, stable environment

- Safety: Fumes are contained instead of spreading through the room

2. Direct Outdoor Exhaust

I use an inline fan that:

- Pulls air from the enclosure

- Creates negative pressure

- Vents directly outdoors

This is the only method that completely removes VOCs and UFPs from the workspace.

When Outdoor Venting Isn’t Possible: Filtration

I don’t rely on filtration alone unless I have to—but when I do, I follow strict rules:

Activated Carbon (For VOCs)

- Required to absorb styrene

- Standard dust filters do nothing for gases

HEPA Filter (For UFPs)

- Must be true HEPA (99.97% @ 0.3 μm)

- Multi-stage systems work best

Important lesson I learned:

Activated carbon saturates. If you don’t replace it regularly, it stops working—and can even re-release trapped chemicals.

Print Quality Bonus: Why Enclosures Also Improve ABS Prints

Safety aside, enclosures dramatically improved my ABS success rate.

ABS shrinks as it cools. Without temperature control, this causes:

- Warping

- Corner lift

- Layer delamination

A warm enclosure slows cooling and keeps temperature differences minimal. The result:

- Stronger layer bonding

- Better dimensional accuracy

- Far fewer failed prints

For me, ventilation wasn’t just a health upgrade—it was a print-quality upgrade too.

Lower-Emission Alternatives I Use When Possible

When ABS isn’t strictly required, I often switch materials:

- PLA – Lowest emissions, mild odor (still ventilate on long prints)

- PETG – Stronger than PLA, fewer emissions than ABS

- ASA – Similar to ABS, better UV resistance

Important note:

ASA still emits styrene. According to multiple lab studies, it still requires ventilation and enclosure, even if the smell is slightly reduced.

Final Verdict: My Professional Recommendation

After years of printing, testing, and researching:

Yes—ABS must be vented. Always.

ABS printing releases:

- Styrene (VOC)

- Ultrafine particles

Ignoring this exposes you to unnecessary health risks and violates basic workplace safety principles recognized by organizations like EPA, CDC, NIOSH, and OSHA.

My Non-Negotiable Rules for ABS:

- Use an enclosure

- Exhaust outdoors whenever possible

- If not, use HEPA + activated carbon

- Replace filters regularly

Safety isn’t optional—it’s part of professional 3D printing.

Frequently Asked Questions (FAQs)

Q1: Why does ABS smell so bad compared to PLA?

I get this question all the time. The short answer is styrene—ABS emits this strong-smelling VOC when heated. PLA is plant-based and mostly emits lactide, which has a mild, sweet odor and way fewer airborne contaminants. That’s why ABS fumes are so much more noticeable (and hazardous) than PLA’s.

Q2: Can I just open a window instead of using an exhaust fan?

Nope. I’ve tried this, and it doesn’t work. Opening a window gives general air flow, but it doesn’t capture fumes at the source. You need an active exhaust fan that creates negative pressure in the enclosure—this ensures contaminated air is pulled out and routed outside, not just spread around your room. Passive venting isn’t enough to mitigate ABS health risks.

Q3: What’s the best filter combination for ABS?

My go-to is a dual-filter setup: a high-efficiency HEPA filter first to trap UFPs, followed by a thick granular activated carbon filter to adsorb VOCs like styrene. This combo covers both types of contaminants you’re dealing with when printing ABS.

Q4: Does ASA filament need to be vented like ABS?

Yes. I’ve seen a lot of people think ASA is “safe” because it has lower emissions, but it still contains styrene. To keep your workspace safe and avoid styrene buildup, you need an enclosure and active ventilation for ASA—just like you do for ABS.