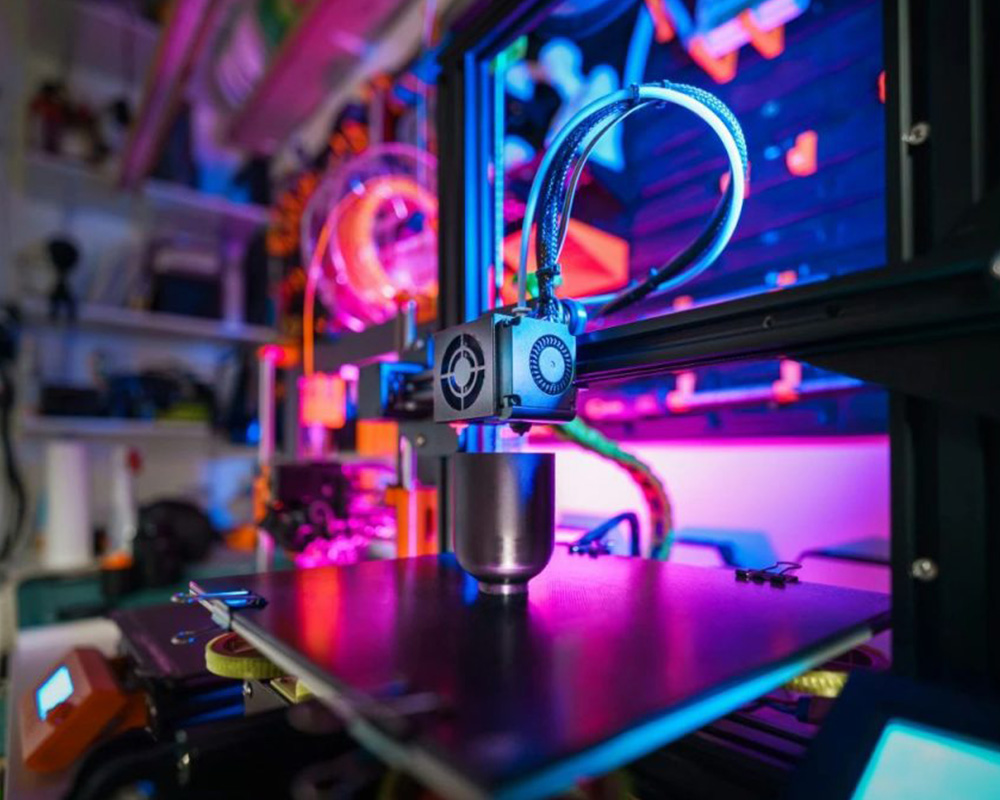

The 3D printing industry has evolved at an unprecedented pace over the past decade, transitioning from a niche prototyping tool to a mainstream manufacturing solution across industries like aerospace, healthcare, automotive, and consumer goods. By 2026, global 3D printing market size is projected to exceed $80 billion, driven by advancements in materials science, printer technology, and process optimization. However, as adoption accelerates, users—from hobbyists and small business owners to large-scale manufacturers—are grappling with a set of pressing concerns that threaten to hinder the full potential of 3D printing.

In this comprehensive guide, we’ll explore the three biggest 3D printer user concerns in 2026: material reliability and sustainability, process consistency and quality control, and cybersecurity and intellectual property (IP) protection. We’ll break down each concern, analyze its root causes, examine real-world implications, and offer actionable strategies to mitigate risks. Additionally, we’ll address common FAQs to provide clarity for users at all experience levels. For more insights on 3D printing best practices, check out our 2026 tools needs for 3D printer maintenance.

1. The 2026 3D Printing Landscape: Context for User Concerns

Before delving into the core concerns, it’s critical to understand the 2026 3D printing ecosystem, as it shapes the challenges users face. Key trends defining the landscape include:

- Industrial Adoption Surge: More than 70% of Fortune 500 companies now use 3D printing for end-part production, up from 45% in 2023. This shift from prototyping to mass manufacturing raises the stakes for reliability and consistency.

- Material Diversification: The number of 3D printing materials has grown 3x since 2020, including high-performance polymers, metal alloys, composite materials, and bio-based resins. While this expands applications, it also introduces complexity in material handling and compatibility.

- Smart Printer Proliferation: 85% of new 3D printers sold in 2026 are “smart” models, equipped with IoT connectivity, AI-driven process monitoring, and cloud-based control systems. These features enhance efficiency but open new cybersecurity vulnerabilities.

- Regulatory Scrutiny: Governments worldwide are implementing stricter regulations for 3D-printed parts, especially in critical industries like healthcare and aerospace. Compliance with standards such as ISO/ASTM 52900 and FDA 21 CFR Part 820 has become a top priority for manufacturers.

Against this backdrop, users are no longer just concerned about basic functionality (e.g., “Can the printer produce a usable part?”) but about more nuanced, high-stakes issues that impact cost, safety, and competitive advantage. Let’s start with the first and most pressing concern: material reliability and sustainability.

2. Biggest Concern: Material Reliability and Sustainability

In 2026, 3D printing materials are the backbone of every application—from a hobbyist’s PLA figurine to a medical implant or an aerospace engine component. However, two interconnected issues dominate user concerns: material reliability (consistent performance and quality) and sustainability (environmental impact and circularity). For users, these issues aren’t just ethical or regulatory—they directly affect part performance, production costs, and brand reputation.

2.1 The Root of Material Reliability Issues in 2026

Material reliability issues stem from three key factors: rapid material innovation outpacing quality control, inconsistent material sourcing, and poor material handling practices. Let’s break down each:

2.1.1 Rapid Innovation vs. Quality Standardization

The 3D printing material market is flooded with new formulations, with manufacturers launching 200+ new materials annually. While innovation is welcome, many of these materials lack standardized testing and certification. For example, a 2025 study by the Additive Manufacturing Technology Association (AMTA) found that 65% of “high-performance” 3D printing polymers lack consistent tensile strength data across batches. This inconsistency is catastrophic for critical applications—imagine a 3D-printed aerospace bracket failing mid-flight due to batch-to-batch material variations.

Smaller material manufacturers, in particular, often cut corners on quality control to compete with industry giants. They may use low-grade base materials, skip aging tests, or fail to account for environmental factors (e.g., humidity, temperature) that affect material performance. For users, this means that even if a material works for one project, the next batch may produce parts that are brittle, porous, or unable to withstand intended use conditions.

2.1.2 Inconsistent Sourcing and Supply Chain Vulnerabilities

Global supply chain disruptions, which have plagued the manufacturing industry since 2020, continue to impact 3D printing material sourcing in 2026. Key raw materials—such as titanium powder for metal 3D printing, PETG resin, and carbon fiber composites—are often sourced from a small number of suppliers, leading to shortages and price volatility. To mitigate shortages, some material manufacturers are switching to alternative suppliers, which can result in changes to material composition without proper disclosure.

For example, a 2026 case study from a leading automotive parts manufacturer found that a batch of 3D-printed ABS parts failed durability tests because the material supplier had substituted a lower-grade styrene monomer to meet demand. The substitution was not disclosed, leading to $2 million in rework costs and a 6-week production delay. This highlights a critical concern for users: they often lack visibility into the full supply chain of 3D printing materials, making it difficult to ensure consistency.

2.1.3 Poor Material Handling and Storage

Even high-quality 3D printing materials can fail if not handled and stored properly. Many materials—especially resins and hygroscopic polymers like Nylon—are sensitive to humidity, temperature, and light. In 2026, with more users adopting 3D printing (including hobbyists and small businesses with limited storage space), improper handling has become a major contributor to material reliability issues.

A survey of 1,000 3D printer users conducted by 3D Printing Industry in early 2026 found that 42% of hobbyists and 35% of small business owners do not use airtight storage containers for their materials, and 28% store materials in areas with fluctuating temperatures (e.g., garages, basements). This leads to moisture absorption, which causes defects like layer adhesion failure, surface roughness, and reduced mechanical strength. For industrial users, while storage practices are more rigorous, cross-contamination between materials (e.g., metal powder mixing) remains a risk, especially in facilities with multiple 3D printing technologies.

2.2 Sustainability: A Growing Concern for 2026 Users

Sustainability has moved from a “nice-to-have” to a “must-have” for 3D printer users in 2026. Driven by consumer demand, regulatory pressure (e.g., the EU’s Circular Economy Action Plan), and corporate sustainability goals, users are increasingly concerned about the environmental impact of 3D printing materials and processes. Key sustainability concerns include:

2.2.1 Single-Use Materials and Waste

Traditional 3D printing processes generate significant waste—support structures, failed prints, and unused material. In 2026, this waste is estimated to be 25-30% of total material usage for FDM/FFF printers and 15-20% for resin printers. Most of this waste is non-recyclable, as 3D printing materials (especially composites and modified polymers) are often difficult to process in standard recycling streams.

Hobbyists and small businesses are particularly affected, as they lack access to industrial recycling programs. Many end up disposing of 3D printing waste in landfills, contributing to plastic pollution. For industrial users, waste disposal costs have risen by 40% since 2023 due to stricter waste management regulations, making sustainability a financial imperative as well as an environmental one.

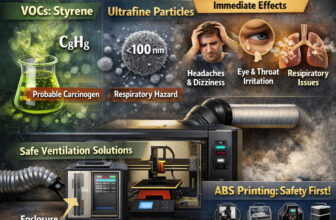

2.2.2 Toxicity of Resins and Metal Powders

Resin 3D printing has grown in popularity in 2026, thanks to its high precision and smooth surface finishes. However, most resin materials contain toxic chemicals (e.g., acrylates, methacrylates) that pose health risks to users and environmental risks if not disposed of properly. A 2025 study by the Environmental Protection Agency (EPA) found that improper disposal of resin waste can contaminate soil and groundwater, with long-term ecological impacts.

Metal 3D printing materials (e.g., titanium, aluminum powders) also raise sustainability concerns. The production of metal powders is energy-intensive, and fine metal particles can be hazardous if inhaled. Additionally, unused metal powder requires careful disposal, as it can be flammable or reactive. For users, especially small businesses and hobbyists, navigating the safe disposal of these materials is both complex and costly.

2.2.3 Lack of Circular Economy Solutions

While the 3D printing industry has talked about circular economy (reusing and recycling materials) for years, viable solutions remain limited in 2026. Few material manufacturers offer take-back programs for waste materials, and recycling technologies for 3D printing materials are expensive and not widely accessible. For example, chemical recycling of resin waste is possible but requires specialized equipment that costs $50,000+—out of reach for most small users.

This lack of circular solutions leaves users with few options to reduce their environmental footprint. A 2026 survey of industrial 3D printing users found that 78% want more sustainable material options but struggle to find cost-effective alternatives to traditional materials.

2.3 Mitigation Strategies for Material Reliability and Sustainability

To address material reliability and sustainability concerns, users can adopt the following strategies:

- Choose Certified Materials: Opt for materials certified by recognized organizations (e.g., ISO/ASTM 52900, UL). Look for manufacturers that provide detailed material data sheets (MDS) and batch traceability. For critical applications, conduct independent testing of material batches.

- Optimize Material Storage: Invest in airtight, temperature-controlled storage solutions (e.g., dry boxes for hygroscopic polymers). Label materials clearly with expiration dates and storage requirements. For industrial users, implement a first-in, first-out (FIFO) inventory system to minimize material aging.

- Partner with Transparent Suppliers: Work with material suppliers that provide full supply chain visibility, including information on raw material sources and manufacturing processes. Negotiate contracts that require disclosure of any material substitutions.

- Adopt Waste Reduction Practices: Use AI-driven slicing software (e.g., PrusaSlicer 5.0, Ultimaker Cura 6.0) to minimize support structures and optimize material usage. Reuse support structures and failed prints where possible—for example, grinding PLA waste into filament for non-critical parts.

- Invest in Sustainable Materials: Switch to bio-based materials (e.g., PLA made from corn starch, PHA from microorganisms) or recycled materials (e.g., PETG made from recycled plastic bottles). Look for materials that are compostable or recyclable in standard streams.

- Use Closed-Loop Systems: For industrial users, invest in closed-loop material recycling systems (e.g., EOS MeltPool Monitoring, HP Multi Jet Fusion Recycling Solution) that allow for the reuse of unused material. Partner with material manufacturers that offer take-back programs for waste.

3. Biggest Concern: Process Consistency and Quality Control

As 3D printing moves from prototyping to end-part production, process consistency and quality control have become the second-biggest concern for users in 2026. For a 3D printing process to be viable for mass production, it must produce parts that meet strict quality standards—every time, across different printers, operators, and production runs. However, 3D printing’s inherent complexity (e.g., layer-by-layer deposition, material melting and solidification) makes consistency difficult to achieve. In 2026, this challenge is amplified by the growing use of distributed 3D printing (e.g., on-demand production at multiple locations) and the integration of AI and IoT into printing processes.

3.1 Why Process Consistency Is a Challenge in 2026

Process consistency issues in 2026 stem from four key factors: the complexity of 3D printing processes, variability in printer performance, human error, and the limitations of quality control tools. Let’s explore each:

3.1.1 Inherent Process Complexity

3D printing is a highly complex process with dozens of variables that can affect part quality. For example, in FDM printing, variables include nozzle temperature, bed temperature, print speed, layer height, infill density, and cooling rate. In metal powder bed fusion (PBF), variables include laser power, scan speed, powder bed thickness, and oxygen levels in the build chamber. Even small variations in these variables can lead to defects like layer separation, warping, porosity, or dimensional inaccuracies.

In 2026, with the adoption of more advanced 3D printing technologies (e.g., multi-material printing, hybrid 3D printing), the number of variables has increased exponentially. For example, multi-material FDM printers require precise control of material flow rates and switching times between materials—any inconsistency can result in poor adhesion between material layers. This complexity makes it difficult for users to optimize and maintain consistent processes.

3.1.2 Variability in Printer Performance

Even printers of the same model can vary in performance, due to differences in manufacturing tolerances, component wear, and calibration. In 2026, with the global 3D printer market growing rapidly, some manufacturers are cutting corners on quality control to meet demand, leading to greater variability between printers. For example, a 2026 test by Consumer Reports found that 30% of FDM printers from a leading brand had inconsistent nozzle temperature control (±5°C), which led to significant variations in part strength.

Component wear is another major issue. Key printer components—such as nozzles, print beds, and laser diodes—degrade over time, leading to changes in performance. For example, a worn FDM nozzle can cause uneven filament extrusion, while a degraded laser in a metal 3D printer can result in inconsistent powder melting. Many users, especially small businesses and hobbyists, fail to replace worn components regularly, leading to a gradual decline in process consistency.

3.1.3 Human Error in Operation and Calibration

Human error remains a significant contributor to process inconsistency in 2026. Even with advanced smart printers, operators play a critical role in setup, calibration, and monitoring. Common human errors include incorrect printer calibration (e.g., bed leveling, filament diameter setting), improper slicer settings, and failure to monitor the print for early signs of defects.

The shortage of skilled 3D printing operators exacerbates this issue. A 2025 report by the Manufacturing Institute found that 60% of 3D printing facilities face a shortage of qualified operators, leading to increased reliance on inexperienced staff. Inexperienced operators are more likely to make calibration errors or miss critical process variations, resulting in inconsistent part quality.

3.1.4 Limitations of Quality Control Tools

Traditional quality control (QC) tools—such as visual inspection, calipers, and tensile testing—are inadequate for 3D printed parts in 2026. Visual inspection misses internal defects (e.g., porosity, internal cracks), while calipers only measure surface dimensions. Tensile testing is destructive, meaning it can’t be used for every part, and it provides limited data on part-to-part variability.

While advanced QC tools—such as X-ray computed tomography (CT) scanning, 3D laser scanning, and AI-driven in-process monitoring—exist, they are often expensive and not widely accessible. For example, a industrial-grade X-ray CT scanner costs $200,000+, putting it out of reach for most small businesses and hobbyists. Even industrial users may struggle to implement real-time QC for high-volume production, as current tools are often slow and require specialized training to operate.

3.2 The Impact of Poor Process Consistency

Poor process consistency has severe implications for users across all sectors. For hobbyists, it means wasted time and material on failed prints. For small businesses, it leads to lost revenue, rework costs, and damage to customer trust. For industrial users, the impact is even more significant—defective parts can lead to product recalls, safety incidents, and non-compliance with regulatory standards.

A 2026 case study from the medical device industry illustrates this point. A manufacturer of 3D-printed orthopedic implants experienced a recall of 1,500 implants after it was discovered that 10% of the implants had internal porosity due to inconsistent laser power in the 3D printing process. The recall cost the company $15 million and damaged its reputation. Additionally, the FDA imposed stricter quality control requirements, leading to a 20% increase in production costs.

Distributed 3D printing—where parts are printed at multiple locations (e.g., retail stores, customer sites)—adds another layer of complexity. Ensuring consistent quality across different printers, operators, and environments is a major challenge for companies adopting this model. For example, a 2026 survey of companies using distributed 3D printing found that 45% reported quality inconsistencies between different printing locations, leading to customer complaints and returns.

3.3 Mitigation Strategies for Process Consistency and Quality Control

To improve process consistency and quality control, users can implement the following strategies:

- Standardize Processes and Slicer Settings: Develop standardized operating procedures (SOPs) for all 3D printing processes, including setup, calibration, and post-processing. Use centralized slicer software with pre-approved settings for different materials and part types. For distributed printing, use cloud-based slicer tools that ensure consistent settings across all printers.

- Invest in Smart Printers with In-Process Monitoring: Choose smart 3D printers equipped with AI-driven in-process monitoring tools (e.g., thermal imaging, layer height sensors, melt pool monitoring). These tools detect defects in real time, allowing operators to adjust the process before the print is completed. For example, the Stratasys F123 Pro 2026 model uses AI to monitor layer adhesion and automatically adjust print speed if issues are detected.

- Regularly Calibrate and Maintain Printers: Establish a regular calibration schedule for printers—including bed leveling, nozzle cleaning, and temperature calibration. Replace worn components (e.g., nozzles, laser diodes) at recommended intervals. Use printer maintenance software to track component wear and receive alerts when maintenance is needed.

- Train Operators Effectively: Invest in comprehensive training for 3D printing operators, covering process optimization, calibration, defect detection, and QC. For small businesses and hobbyists, take advantage of online training resources to build skills. For industrial users, implement a mentorship program to pair inexperienced operators with experts.

- Adopt Advanced QC Tools: For critical applications, invest in advanced QC tools like X-ray CT scanning (for internal defects) and 3D laser scanning (for dimensional accuracy). For high-volume production, use automated QC systems that integrate with 3D printers to provide real-time feedback. For small businesses, consider third-party QC services that offer affordable testing for 3D printed parts.

- Implement Statistical Process Control (SPC): Use SPC techniques to monitor process variables and identify trends that may lead to defects. Collect data on key process parameters (e.g., nozzle temperature, print speed) and part quality metrics (e.g., dimensional accuracy, tensile strength). Use this data to optimize the process and prevent defects before they occur.

4. Biggest Concern: Cybersecurity and Intellectual Property (IP) Protection

The third-biggest concern for 3D printer users in 2026 is cybersecurity and intellectual property (IP) protection. As 3D printers become more connected (via IoT, cloud, and AI), they are increasingly vulnerable to cyberattacks. Additionally, the digital nature of 3D printing files makes IP theft easier than ever—pirated 3D models and counterfeit parts are a growing problem across industries. For users, these issues pose significant risks: cyberattacks can disrupt production, compromise part quality, and steal sensitive data, while IP theft can lead to lost revenue, legal disputes, and damage to brand reputation.

4.1 Cybersecurity Risks for 3D Printers in 2026

In 2026, 3D printers are part of the broader industrial IoT (IIoT) ecosystem, making them targets for cybercriminals. Key cybersecurity risks include:

4.1.1 Unauthorized Access to Printers and Networks

Most smart 3D printers use Wi-Fi or Ethernet to connect to networks, allowing operators to control them remotely. However, many users fail to secure these connections—using weak passwords, outdated firmware, or unencrypted data transmission. This makes it easy for cybercriminals to gain unauthorized access to printers and the broader network.

A 2026 report by the Cybersecurity and Infrastructure Security Agency (CISA) found that 70% of 3D printers are vulnerable to unauthorized access due to poor security practices. Once accessed, cybercriminals can modify print settings (leading to defective parts), steal sensitive data (e.g., 3D models, production schedules), or use the printer as a gateway to attack other devices on the network.

4.1.2 Malware and Ransomware Attacks

Malware and ransomware attacks on 3D printing systems are on the rise in 2026. Cybercriminals use phishing emails, malicious software downloads, or compromised 3D model files to install malware on printers or connected devices. Ransomware attacks are particularly devastating—cybercriminals encrypt 3D printing files, printer controls, or production data and demand a ransom to restore access.

For example, in early 2026, a major aerospace manufacturer was hit by a ransomware attack that targeted its 3D printing systems. The attack encrypted 10,000+ 3D model files and disabled 20 industrial 3D printers, leading to a 2-week production shutdown. The manufacturer paid a $2 million ransom to restore access, but the incident also resulted in a regulatory investigation into data security practices.

4.1.3 Supply Chain Attacks on Printer Firmware and Software

Supply chain attacks—where cybercriminals compromise hardware or software during production—are a growing threat to 3D printer users. In 2026, several high-profile cases involved cybercriminals tampering with 3D printer firmware during manufacturing, allowing them to gain remote access to printers once they are deployed.

Software supply chain attacks are also common. Slicer software, 3D model libraries, and printer management tools can be compromised to install malware or steal data. For example, a popular slicer software update in 2026 was found to contain hidden code that collected user data (e.g., 3D model files, printer settings) and sent it to a third-party server. The incident affected 500,000+ users worldwide.

4.2 IP Protection Risks in 2026

The digital nature of 3D printing makes IP protection a major challenge. 3D models are easy to copy, share, and modify, leading to widespread piracy and counterfeiting. Key IP risks include:

4.2.1 Piracy of 3D Models

In 2026, there are millions of 3D models available online, many of which are pirated. Hobbyists and small businesses often download pirated models to save money, unaware of the legal risks. For designers and manufacturers, piracy leads to lost revenue—according to the 3D Printing Association, piracy costs the 3D model industry $1.2 billion annually.

Pirated models are also often low-quality or modified, leading to defective prints. For example, a hobbyist who downloads a pirated 3D model of a drone part may find that the part is dimensionally inaccurate, leading to a crash. For industrial users, using pirated models in production can result in non-compliance with regulatory standards and legal liability.

4.2.2 Counterfeiting of 3D-Printed Parts

Counterfeiting of 3D-printed parts is a growing problem in industries like automotive, healthcare, and aerospace. Cybercriminals copy 3D models of genuine parts, produce low-quality counterfeits, and sell them as authentic. These counterfeit parts are often unsafe—for example, a counterfeit 3D-printed brake pad may fail under stress, leading to a car accident.

In 2026, the FDA reported a 50% increase in counterfeit 3D-printed medical devices (e.g., hearing aids, dental implants) over the past two years. These counterfeits lack proper testing and certification, posing significant health risks to patients. For manufacturers, counterfeiting damages brand reputation and leads to lost sales.

4.2.3 Inadequate Legal Protection for 3D Printing IP

Current IP laws were not designed for 3D printing, leading to ambiguity and challenges in enforcement. In many countries, it’s unclear whether 3D models qualify for copyright protection, and enforcing IP rights against global counterfeiters is difficult and costly. For small businesses and independent designers, legal action against pirates is often prohibitively expensive, leaving them with few options to protect their work.

4.3 Mitigation Strategies for Cybersecurity and IP Protection

To address cybersecurity and IP protection concerns, users can implement the following strategies:

- Secure Printer Networks and Connections: Use strong, unique passwords for 3D printers and connected devices. Enable encryption (e.g., WPA3 for Wi-Fi, TLS for cloud connections) to protect data transmission. Isolate 3D printers on a separate network (air-gapped if possible) to prevent access to critical business systems.

- Keep Firmware and Software Updated: Regularly update printer firmware, slicer software, and other 3D printing tools to patch security vulnerabilities. Enable automatic updates where possible, but verify updates from trusted sources before installing. Avoid downloading software or firmware from untrusted websites.

- Implement Access Controls: Use role-based access control (RBAC) to restrict access to 3D printers and 3D model files. Only allow authorized operators to modify print settings or access sensitive data. Use multi-factor authentication (MFA) for remote access to printers and cloud-based 3D printing platforms.

- Use Antivirus and Endpoint Protection: Install antivirus software and endpoint protection tools on devices connected to 3D printers. Scan 3D model files and software downloads for malware before use. Use email filtering to block phishing emails that may contain malicious links or attachments.

- Protect 3D Models with Digital Rights Management (DRM): For designers and manufacturers, use DRM software to protect 3D models. DRM tools can restrict copying, sharing, and modification of models, and track usage to detect unauthorized access. For example, tools like Digimarc 3D DRM embed invisible watermarks in models to identify pirated copies.

- Only Use Licensed 3D Models: Avoid pirated 3D models—purchase models from reputable platforms (e.g., Licensed 3D Model Marketplace) that offer legal protection. Read and understand the terms of use for 3D models to ensure compliance with IP laws.

- Educate Users on Cybersecurity and IP Risks: Train operators and employees on cybersecurity best practices (e.g., identifying phishing emails, creating strong passwords) and IP laws. Raise awareness of the risks of using pirated models or unsecure connections.

- Develop a Cybersecurity Incident Response Plan: Create a plan to respond to cybersecurity incidents (e.g., ransomware attacks, unauthorized access). The plan should include steps to isolate affected devices, restore data from backups, and notify relevant stakeholders (e.g., customers, regulators). Test the plan regularly to ensure effectiveness.

5. FAQs: Addressing Common 3D Printer User Concerns in 2026

Below are answers to frequently asked questions about the biggest 3D printer user concerns in 2026. These FAQs are designed to provide clarity for users at all experience levels, from hobbyists to industrial manufacturers.

Q1: What is the most reliable 3D printing material for industrial applications in 2026?

For industrial applications, the most reliable 3D printing materials in 2026 are those that are certified to meet industry standards and have a proven track record of consistency. For metal parts, titanium alloy (Ti6Al4V) and Inconel 718 are popular choices, as they offer high strength and corrosion resistance and are certified for aerospace and medical applications. For polymer parts, PEEK and ULTEM are reliable high-performance options, while ABS filament and PETG filament are cost-effective choices for less critical applications. Always choose materials from reputable manufacturers that provide detailed MDS and batch traceability.

Q2: How can small businesses afford advanced quality control tools for 3D printing?

Small businesses don’t need to invest in expensive industrial-grade QC tools to ensure part quality. Instead, they can adopt cost-effective alternatives: 1) Use desktop 3D scanners (e.g., EinScan-SE 2026, Revopoint Pop 3) for dimensional accuracy checks—these scanners cost $500-$2,000, which is manageable for most small businesses. 2) Partner with third-party QC labs that offer affordable testing services (e.g., tensile testing, porosity analysis) on a per-part or per-project basis. 3) Use AI-driven slicing software with built-in quality checks (e.g., Ultimaker Cura 6.0) that identify potential defects before printing. Additionally, many small businesses qualify for grants or tax incentives for investing in manufacturing quality control tools—check with local economic development agencies for opportunities.

Q3: Are smart 3D printers more vulnerable to cyberattacks than traditional printers?

Yes, smart 3D printers are more vulnerable to cyberattacks than traditional (non-connected) printers, due to their IoT connectivity and cloud integration. However, this vulnerability can be mitigated with proper security practices (e.g., secure networks, access controls, firmware updates). In fact, smart printers can offer better security than traditional printers in some cases, as they often include built-in security features (e.g., encryption, MFA) that traditional printers lack. The key is to use smart printers responsibly—avoiding weak passwords, keeping software updated, and isolating printers on separate networks.

Q4: How can I protect my 3D models from being pirated?

To protect your 3D models from piracy, use a combination of DRM software, watermarking, and legal protections: 1) Use DRM tools (e.g., Digimarc 3D DRM, Sculpteo DRM) to restrict copying, sharing, and modification of your models. These tools can also track usage to detect unauthorized access. 2) Embed invisible watermarks in your models—watermarks can be used to prove ownership if piracy occurs. 3) Register your 3D models for copyright protection—this provides legal recourse if your models are pirated. 4) Sell your models through reputable platforms that have anti-piracy measures in place (e.g., Shapeways, Thingiverse Premium). Additionally, educate your customers on the importance of using licensed models to reduce demand for pirated copies.

Q5: What are the most sustainable 3D printing materials available in 2026?

The most sustainable 3D printing materials in 2026 are bio-based, recycled, or compostable. Key options include: 1) PLA (Polylactic Acid) made from corn starch or sugarcane—PLA is compostable and requires less energy to produce than traditional plastics. 2) PHA (Polyhydroxyalkanoates) made from microorganisms—PHA is biodegradable and can be produced from organic waste. 3) Recycled PETG and ABS—made from recycled plastic bottles and other plastic waste. 4) Bio-based resins—resins made from plant-based materials (e.g., soy, hemp) that are less toxic than traditional resins. When selecting sustainable materials, look for certifications like ASTM D6400 (compostable) or ISO 14021 (recycled content) to ensure environmental claims are valid.

Q6: How can I ensure process consistency across multiple 3D printers in different locations?

To ensure process consistency across multiple 3D printers in different locations, use centralized management and standardization: 1) Use cloud-based 3D printing management software (e.g., Ultimaker Digital Factory, Stratasys GrabCAD Print) to control slicer settings, print jobs, and printer calibration from a single dashboard. This ensures that all printers use the same settings. 2) Develop standardized operating procedures (SOPs) for setup, calibration, and post-processing, and train all operators to follow these procedures. 3) Use the same model of printer and material across all locations to minimize variability. 4) Implement regular audits of each location to ensure compliance with SOPs and quality standards. For distributed manufacturing teams, consider using a centralized training program to ensure all operators have the same skills and knowledge.

6. Conclusion: Addressing Concerns to Unlock 3D Printing’s Potential

In 2026, 3D printing offers enormous potential for innovation and efficiency across industries, but material reliability and sustainability, process consistency and quality control, and cybersecurity and IP protection remain the biggest barriers to widespread adoption. These concerns are interconnected—for example, poor material reliability can undermine process consistency, while smart printers that improve consistency introduce cybersecurity risks. However, with the right strategies—such as using certified materials, investing in smart printers with in-process monitoring, and implementing robust cybersecurity measures—users can mitigate these risks and unlock the full potential of 3D printing.

As the 3D printing industry continues to evolve, it’s critical for users to stay informed about emerging concerns and solutions. By prioritizing reliability, consistency, and security, users can build trust in 3D printing as a viable manufacturing solution and drive further innovation. Whether you’re a hobbyist, a small business owner, or an industrial manufacturer, addressing these concerns is key to success in the 2026 3D printing landscape.