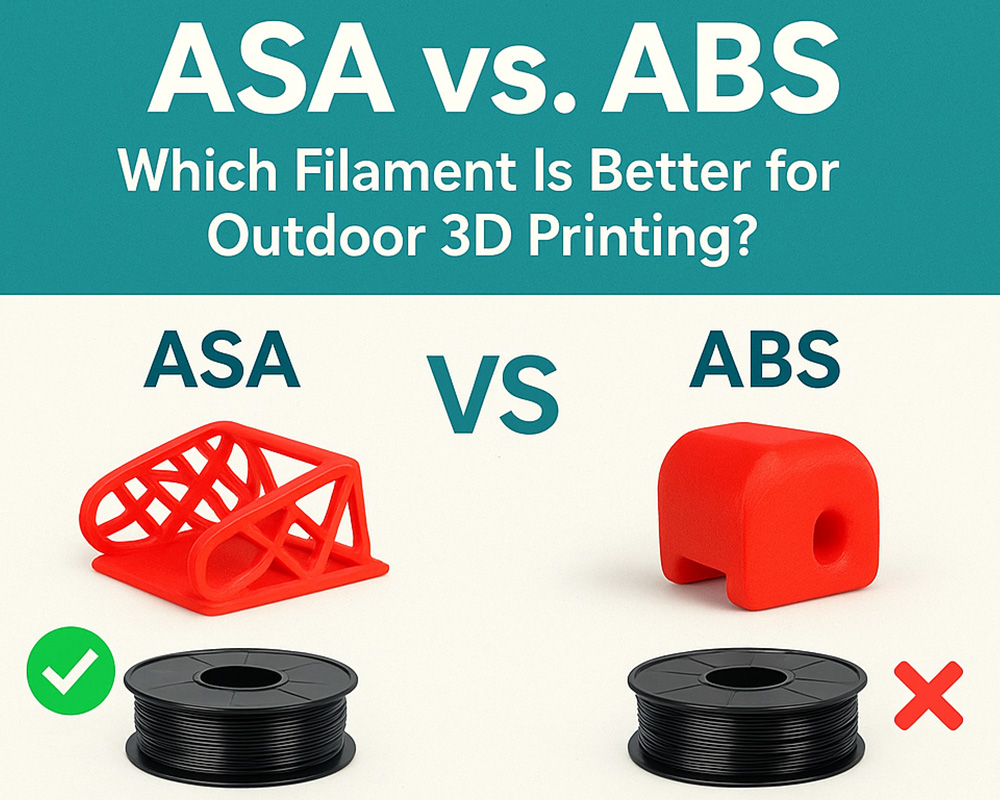

In the world of FDM 3D printing, a handful of materials dominate everyday use. PLA covers the basics, PETG handles general durability, and ABS has long been the standard for functional, impact-resistant parts. But in the last few years, a new contender has risen in popularity: ASA, a filament specifically engineered to survive harsh outdoor environments.

If you’ve ever printed something meant to live outside—garden fixtures, automotive trims, weather-exposed casings—you’ve probably encountered the dreaded problem of fading, cracking, or warping after a few weeks under the sun. ABS works well indoors, but outdoors it often struggles. ASA, however, was designed for the exact conditions that challenge ABS.

So the big question becomes:

Is ASA worth upgrading to if you regularly print outdoor-exposed parts?

And equally important: What do you gain, lose, or compromise by choosing ASA over ABS?

This in-depth guide will help you make that decision. Throughout this article, we’ll explore material properties, mechanical performance, printing experience, long-term durability, use-case differences, and cost considerations—giving you a complete, expert-level comparison between ASA and ABS.

Table of Contents

- Introduction

- What Is ABS? A Technical Overview

- What Is ASA? How It Differs at the Polymer Level

- Mechanical Comparison: Strength, Durability & Fatigue Resistance

- Thermal Behavior: Heat Deflection vs. Real-World Temperature Stability

- UV Resistance and Weather Resistance

- Chemical Resistance and Environmental Stability

- Printability: Warping, Layer Adhesion & Difficulty

- Surface Finish, Post-Processing & Aesthetic Longevity

- Long-Term Outdoor Performance: Real-World Behavior

- When ABS Makes More Sense

- When ASA Is Clearly the Better Choice

- Cost Analysis: Is the Upgrade Worth It Financially?

- Environmental Considerations

- Troubleshooting ASA and ABS: Common Printing Challenges

- Expert Recommendations for Outdoor Prints

- FAQs

- Conclusion

1. Introduction

3D printing has become a powerful tool for producing functional components, prototypes, and long-lasting parts. As users move beyond decorative prints and into functional engineering, material selection matters more than ever. The difference between a print that lasts a month and one that lasts years often comes down to the filament used.

ABS (Acrylonitrile Butadiene Styrene) is a well-known, engineering-grade material favored for its toughness, heat resistance, and post-processing friendliness. However, its outdoor performance is limited, especially in regard to UV exposure.

ASA (Acrylonitrile Styrene Acrylate), while chemically related to ABS, was engineered specifically to solve ABS’s weaknesses—particularly its vulnerability to sunlight, weather, and long-term environmental stress.

This article analyzes both materials thoroughly to determine whether upgrading to ASA is worth it for outdoor prints—and when ABS might still be the better choice.

2. What Is ABS? A Technical Overview

ABS is one of the earliest mainstream 3D printing filaments and is still widely used in consumer and industrial applications. It is a terpolymer composed of acrylonitrile, butadiene, and styrene.

Key Properties of ABS

- Good impact strength

- High heat resistance compared to PLA and PETG

- Excellent machinability and post-processing flexibility

- Lightweight and durable

- Affordable and widely available

ABS is an excellent choice for parts that need to withstand mechanical loads or elevated temperatures. It is commonly found in:

- Electronic housings

- Automotive interior components

- Lego bricks

- Durable consumer goods

ABS Weaknesses

Despite its strengths, ABS has several limitations—particularly for outdoor use:

- Poor UV resistance, leading to fading, discoloration, and brittleness

- Moderate warping, requiring controlled printing conditions

- Sensitivity to prolonged environmental exposure

ABS is excellent indoors but lacks the long-term stability required for harsh outdoor environments. Learn more: What Is 3D Printer Filament ABS?

3. What Is ASA? How It Differs at the Polymer Level

ASA was developed as a weather-resistant alternative to ABS. Chemically, it replaces the butadiene elastomer in ABS with an acrylic elastomer, significantly improving UV and weather stability.

Key Advantages of ASA

- Outstanding UV resistance

- Superior color stability

- Reduced yellowing and fading

- Higher outdoor durability

- Very good heat resistance

- Lower sensitivity to environmental degradation

These improvements make ASA a common material in:

- Automotive exterior parts

- Outdoor equipment housings

- Marine applications

- Signage and outdoor fixtures

ASA preserves the mechanical characteristics that make ABS successful, while adding properties necessary for external environments.

4. Mechanical Comparison: Strength, Durability & Fatigue Resistance

At the mechanical level, ABS and ASA are relatively similar. They both deliver:

- Good tensile strength

- Impact resistance

- Moderate flexibility

- Solid layer adhesion when printed correctly

ABS Mechanical Characteristics

- Slightly higher impact resistance

- Good flexibility under repeated load

- Well-known mechanical behavior due to decades of use

ASA Mechanical Characteristics

- Equal or slightly higher tensile strength

- Slightly lower impact resistance (though still high)

- Better long-term stability under mechanical stress when exposed to UV

Real-World Summary

If mechanical performance alone is the deciding factor:

- ABS might edge out ASA for indoor, high-impact components.

- ASA wins for any application involving sunlight or weather exposure, where ABS quickly loses mechanical integrity.

5. Thermal Behavior: Heat Deflection vs. Real-World Temperature Stability

Both materials are thermoplastics designed to handle higher temperatures than PLA.

ABS Thermal Characteristics

- Heat deflection temperature around 95–105°C

- Good performance near car-interior temperatures

- Susceptible to long-term heat oxidation outdoors

ASA Thermal Characteristics

- Heat deflection temperature also around 95–105°C

- More stable under prolonged heat exposure

- Less prone to deformation under sunlight (due to UV stability and chemical resistance)

In hot climates, ASA generally survives better outdoors, especially in direct sunlight, where ABS can deform sooner.

6. UV Resistance and Weather Resistance

This is where ASA’s advantage becomes undeniable.

ABS Outdoors

- Discolors rapidly

- Can become chalky or brittle

- Cracks more easily over time

- Structural degradation can begin in weeks or months

ASA Outdoors

- Exceptional UV resistance

- Maintains color for years

- Resists cracking and brittleness

- Designed for sun-exposed environments

ASA was literally engineered for outdoor applications. UV protection is not an afterthought—it is the defining reason for the material’s existence.

7. Chemical Resistance and Environmental Stability

Both ABS and ASA are resistant to a variety of chemicals, including oils and greases. But ASA is more stable in challenging environments.

ABS Chemical Behavior

- Sensitive to long-term oxidation

- Can absorb moisture under extreme conditions

- Loses mechanical performance under UV exposure

ASA Chemical Behavior

- Higher resistance to oxidation

- Better moisture resistance

- Stable under UV and weathering

- More resistant to environmental stress cracking

For parts used near water, sunlight, or automotive fluids, ASA is typically superior.

8. Printability: Warping, Layer Adhesion & Difficulty

ABS is famously challenging due to warping.

ABS Printability

- Requires an enclosure

- Prone to layer separation and corner lift

- Emits noticeable fumes (should be ventilated)

- Narrow optimal temperature window

ASA Printability

- Similar to ABS but slightly more forgiving

- Some blends warp less

- Produces fewer odors than ABS (though still requires ventilation)

- Works very well in enclosed printers

While neither material is as easy as PLA or PETG, many users find ASA slightly easier than ABS due to reduced shrinkage and better interlayer bonding in some formulations.

9. Surface Finish, Post-Processing & Aesthetic Longevity

Both ABS and ASA accept sanding, machining, and painting extremely well.

ABS Finish

- Excellent for vapor smoothing

- Takes paint easily

- Fades quickly outdoors

ASA Finish

- Slightly smoother surface out of the printer

- Resists yellowing and fading

- Excellent long-term aesthetic stability

- Can also be vapor smoothed (with the right solvents)

For prints where appearance matters over time—such as signs, casings, or decorative outdoor objects—ASA maintains its look far better.

10. Long-Term Outdoor Performance: Real-World Behavior

ABS outdoors:

- Loses color in weeks

- Surface texture degrades

- Cracks after prolonged UV exposure

- Often becomes brittle

ASA outdoors:

- Maintains structural integrity

- Resists yellowing for years

- Survives rain, snow, and high heat

- Remains mechanically stable

If your project needs to last more than a few months outside, ASA is the clear winner.

11. When ABS Makes More Sense

Despite its limitations, ABS remains an excellent engineering material for indoor applications.

Choose ABS when:

- Cost is the primary factor

- The part will be used exclusively indoors

- You need excellent impact resistance

- You want vapor-smooth finishing with acetone

- You’re already familiar with ABS and comfortable printing it

In controlled environments, ABS performs exceptionally well.

12. When ASA Is Clearly the Better Choice

ASA is the superior material for:

- Outdoor tools and functional parts

- Automotive exterior components

- Garden fixtures

- Marine environments

- Sun-exposed enclosures

- Outdoor signage

- Long-term external installations

If a print will see sunlight, moisture, heat cycles, or weather exposure, ASA is almost always the better investment.

13. Cost Analysis: Is the Upgrade Worth It Financially?

ASA is generally more expensive than ABS—sometimes by 15–30%.

However, consider lifespan:

- ABS outdoor lifespan: months

- ASA outdoor lifespan: years

For outdoor projects, ASA’s durability often reduces replacement frequency, saving time and material in the long run.

Cost Efficiency Conclusion

If your part is outdoors for more than a few months, ASA pays for itself.

14. Environmental Considerations

Both materials are petrochemical-based, but:

- ABS often requires more reprints due to outdoor degradation.

- ASA’s longevity reduces material waste.

- ASA’s stability may reduce chemical leaching in outdoor conditions.

Neither is biodegradable, but ASA’s extended lifespan makes it more environmentally efficient in applications requiring long-term durability.

15. Troubleshooting ASA and ABS: Common Printing Challenges

Common ABS Issues

- Warping: Use enclosure, brims, and high bed temperature.

- Layer splitting: Increase nozzle temp or enclosure temp.

- Odor: Improve ventilation.

Common ASA Issues

- Minor warping: Similar to ABS solutions.

- Over-drying can cause brittleness—store filament properly.

- Surface shine varies by brand; tune cooling settings for consistency.

ASA prints best with low fan speeds, while ABS usually prefers the fan completely off.

16. Expert Recommendations for Outdoor Prints

If you plan to create parts for environments involving:

- UV exposure

- Rain or snow

- Daily temperature swings

- Extended sun exposure

- High humidity

- Wind and mechanical wear

then ASA should be your default choice.

ABS still serves as a reliable indoor material, but for outdoor projects, ASA is a significant upgrade in reliability and longevity.

17. FAQs

Q1: Is ASA stronger than ABS?

Both have similar strength, though ABS may have slightly higher impact resistance. ASA has better long-term stability outdoors.

Q2: Can I print ASA without an enclosure?

Technically yes, but results vary. An enclosure is strongly recommended to reduce warping.

Q3: Does ASA fade in the sun?

ASA is engineered to resist UV fading and yellowing. It maintains color much longer than ABS.

Q4: Is ASA more heat-resistant than ABS?

Both have similar heat resistance, but ASA handles prolonged heat exposure better outdoors.

Q5: Does ASA produce fumes like ABS?

It produces fewer noticeable odors, but both should be printed with adequate ventilation.

Q6: Is ASA worth the extra cost?

If your part is outdoors, absolutely. If it’s strictly indoors, ABS may be more cost-efficient.

Q7: Can ASA be acetone smoothed like ABS?

Some ASA blends can be vapor smoothed, but not all react the same way as ABS. Always test on scrap material.

18. Conclusion

ASA and ABS share many mechanical and thermal properties, but their differences become clear when the environment shifts outdoors. ABS remains a dependable, affordable engineering material for indoor parts, offering strength, machinability, and versatility.

However, for extended outdoor use, ABS struggles with UV exposure and environmental degradation. Prints may fade, crack, and weaken far sooner than expected.

ASA was designed precisely to solve these issues. Its outstanding UV resistance, weather stability, and long-term durability make it the superior choice for any project exposed to the elements. The slight increase in material cost is far outweighed by the longevity and reliability of the final prints.

Final Verdict:

For outdoor applications, ASA is unquestionably worth the upgrade.

For indoor applications, ABS remains a cost-effective and dependable option.