3D printing has reached a point where strength, durability, and engineering-grade performance are no longer considered niche requirements. Designers, engineers, and hobbyists are now turning to tougher materials to create parts that function reliably in real-world conditions—whether they’re gears, brackets, outdoor equipment, structural components, or prototypes that must withstand repeated use.

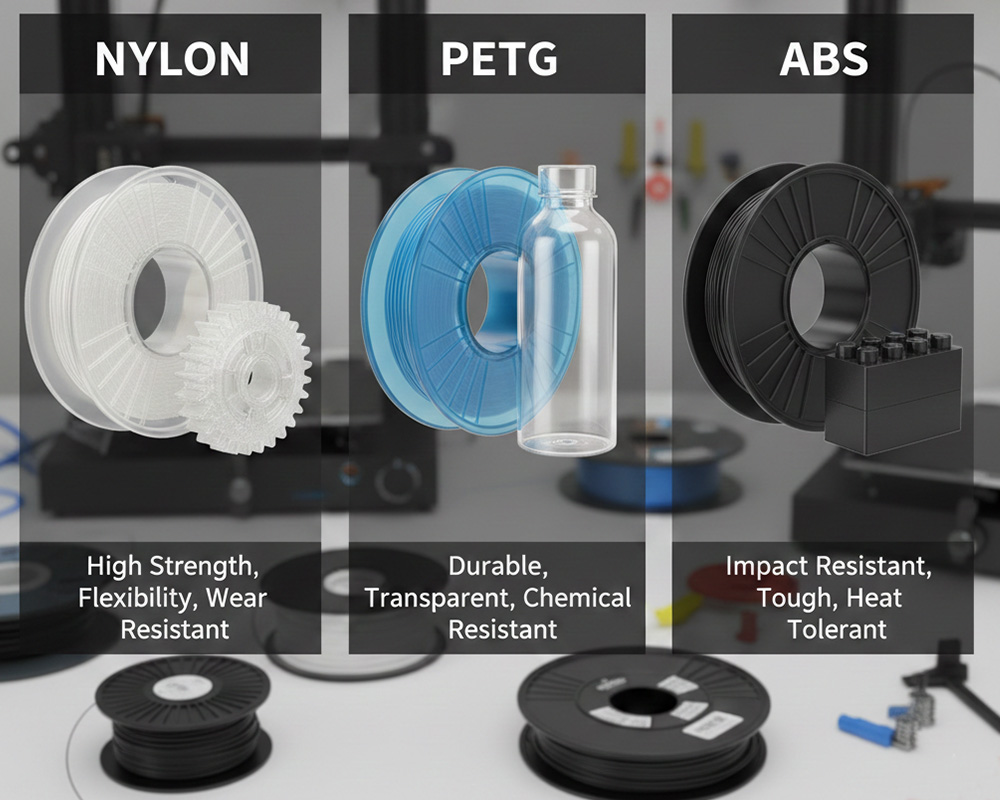

Among the many materials available for FDM/FFF printers, Nylon, PETG, and ABS stand out as the leading choices for durable, high-strength printing. Each carries a unique combination of mechanical properties, printing characteristics, and long-term performance capabilities. Yet the question remains:

Which material is actually the best for strong, reliable prints?

To answer that question, this guide breaks down these three popular filaments in detail—covering strength metrics, durability, heat and chemical resistance, printing difficulty, long-term performance, cost, use cases, and more. The goal is simple: help you choose the material that best fits your functional printing needs.

1. Understanding What “Durable” and “High-Strength” Really Mean in 3D Printing

Before comparing materials, it’s important to define what durability and strength mean in the context of FDM printing. These terms are often used interchangeably, but technically they refer to different mechanical characteristics.

1.1 Strength

Strength refers to how well a material withstands forces applied in tension, compression, or bending. Relevant measures include:

- Tensile strength (resistance to pulling forces)

- Compressive strength (resistance to squeezing or crushing)

- Flexural strength (resistance to bending)

- Layer adhesion strength (interlayer bonding)

For engineering-grade performance, strength must be consistent both within individual layers and between layers.

1.2 Durability

Durability encompasses long-term performance under repeated stress or harsh environments. It includes:

- Impact resistance

- Fatigue resistance

- Abrasion resistance

- UV stability

- Chemical resistance

- Heat tolerance

- Moisture stability (or sensitivity)

A durable material may not always be the strongest in a laboratory test—but it performs reliably over time in real-world applications.

1.3 Practical Requirements for Functional Parts

When evaluating Nylon, PETG, and ABS, several practical factors matter equally to mechanical performance:

- Ease of printing

- Warping tendencies

- Need for an enclosure

- Bed adhesion

- Resistance to cracking

- Cost and availability

- Material maintenance (e.g., drying requirements)

This multi-factor approach is what engineers and prototyping professionals use when deciding which filament to deploy for specific applications.

2. Nylon Filament: The Engineering Powerhouse

Nylon—also known by material families such as PA6, PA12, or co-polymer blends—remains one of the strongest, most reliable materials available on consumer and industrial FDM printers.

2.1 Mechanical Strength

Nylon’s mechanical performance is exceptional, especially in terms of tensile strength and toughness. Its ability to deform slightly before breaking gives it an advantage in applications requiring both strength and resilience.

Key properties:

- High tensile strength

- Excellent impact resistance

- Outstanding fatigue resistance

- Superior layer adhesion in well-tuned settings

- High toughness compared to most FDM materials

Unlike brittle plastics, Nylon bends before breaking, making it ideal for functional components that undergo repeated use.

2.2 Durability and Environmental Resistance

Nylon is well known for durability in real-world applications, which is why it’s used in gears, bearings, automotive parts, and tools.

Durability highlights:

- Very high abrasion resistance

- Good chemical resistance

- Excellent fatigue life (parts can endure cyclic loads)

- High wear resistance

- Suitable for moving mechanisms and load-bearing parts

However, Nylon does have one notable drawback: moisture absorption. Nylon absorbs water from the environment, which can:

- Reduce strength

- Affect dimensional stability

- Cause hydrolysis during printing (if filament is not dry)

Drying Nylon is therefore essential for optimal performance.

2.3 Printing Characteristics

Nylon is not the easiest filament to print, but with proper equipment and tuning it becomes manageable.

Requirements:

- High nozzle temperature (240°C–280°C)

- Heated bed (60°C–80°C)

- Enclosure recommended for consistent layer bonding

- Filament must be dried before use

The material’s tendency to warp is less severe than ABS, but more significant than PETG.

2.4 Best Applications for Nylon

Nylon excels in applications involving mechanical stress, abrasion, and repeated movement.

Common uses:

- Gears

- Hinges

- Living parts (clip mechanisms)

- Tools

- Drone components

- Mechanical brackets

- Robotics components

- Industrial prototypes

In performance-critical applications, Nylon often outperforms both PETG and ABS.

3. PETG Filament: The Balanced Performer

PETG (Polyethylene Terephthalate Glycol) occupies the middle ground between PLA and ABS, combining ease of printing with strong mechanical properties and excellent durability.

3.1 Mechanical Strength

PETG’s tensile strength is typically higher than ABS and close to certain Nylon blends, but its layer adhesion characteristics are especially strong.

Strength characteristics:

- High tensile strength

- Very good layer bonding

- Less brittle than PLA or ABS

- Moderate impact resistance

While PETG does not match Nylon’s toughness, it outperforms many other consumer filaments.

3.2 Durability and Environmental Resistance

PETG is often chosen for parts requiring long-term durability, stability, and weather resistance.

Durability benefits:

- Excellent UV resistance (better than ABS)

- Good chemical resistance

- Less prone to cracking

- Minimal warping compared to ABS

- Suitable for outdoor use

Unlike Nylon, PETG filaments does not absorb large amounts of moisture, making it more dimensionally stable.

3.3 Printing Characteristics

One of PETG’s main advantages is its user-friendliness.

Printing characteristics:

- Prints at moderate temperatures (230°C–250°C)

- Heated bed recommended but not always essential

- Minimal warping

- No need for enclosure

- Extremely strong layer adhesion (sometimes even too strong—stringing and oozing are common)

PETG is a natural choice for those who want a strong, durable print without the challenges of ABS or the material maintenance of Nylon.

3.4 Best Applications for PETG

PETG performs well in applications requiring strength, visual quality, and environmental stability.

Common uses:

- Functional prototypes

- Outdoor fixtures

- Enclosures

- Mechanical brackets

- Household tools

- Structural parts with moderate loads

- Weather-exposed components

Its balance of durability, rigidity, and printability makes it one of the best all-around filaments for general-purpose strong printing.

4. ABS Filament: The Classic Engineering Material

ABS (Acrylonitrile Butadiene Styrene) has long been a go-to material for durable plastic parts in consumer products—everything from automotive components to electronic housings to LEGO bricks.

4.1 Mechanical Strength

ABS offers solid strength, though slightly lower than Nylon in tensile performance and lower than PETG in layer bonding.

Strength characteristics:

- Good tensile strength

- High impact resistance

- Good flexural strength

- Adequate toughness

- Better heat resistance than PLA or PETG

ABS is not as strong as Nylon, but its mechanical properties are more predictable than many other consumer-grade materials.

4.2 Durability and Environmental Stability

While strong, ABS does not match PETG or Nylon in some aspects of long-term durability.

Durability features:

- High heat resistance

- Good chemical resistance

- Moderate abrasion resistance

- Sensitive to UV exposure (can degrade outdoors)

ABS is better suited to indoor mechanical components than prolonged outdoor use.

4.3 Printing Characteristics

ABS is known for being difficult to print—primarily due to warping and layer separation.

Requirements:

- High nozzle temperatures (230°C–260°C)

- Heated bed (90°C–110°C mandatory)

- Enclosure strongly recommended

- Warping common without controlled thermal environment

- Emission of fumes requires proper ventilation

Despite these challenges, ABS filaments remains a staple for many engineers due to its predictable performance.

4.4 Best Applications for ABS

ABS is widely used for:

- Automotive interior components

- Electronic housings

- Jigs and fixtures

- Functional prototypes

- Mechanically loaded parts indoors

- Components requiring higher heat resistance

Its thermal and mechanical reliability make it a strong choice for industrial applications—provided the printing setup is adequate.

5. Direct Comparison: Nylon vs. PETG vs. ABS

This section provides a side-by-side evaluation of key characteristics.

5.1 Strength Comparison

| Property | Nylon | PETG | ABS |

| Tensile strength | ★★★★★ | ★★★★☆ | ★★★☆☆ |

| Layer adhesion | ★★★★★ | ★★★★★ | ★★★☆☆ |

| Impact resistance | ★★★★★ | ★★★★☆ | ★★★★☆ |

| Fatigue resistance | ★★★★★ | ★★★☆☆ | ★★★☆☆ |

| Stiffness | ★★☆☆☆ | ★★★☆☆ | ★★★★★ |

Winner: Nylon for overall mechanical performance.

Runner-up: PETG for general-purpose strength.

5.2 Durability Comparison

| Property | Nylon | PETG | ABS |

| Abrasion resistance | ★★★★★ | ★★★☆☆ | ★★★☆☆ |

| Heat resistance | ★★★★☆ | ★★★☆☆ | ★★★★★ |

| UV resistance | ★★★☆☆ | ★★★★★ | ★★☆☆☆ |

| Chemical resistance | ★★★★☆ | ★★★★☆ | ★★★☆☆ |

| Moisture resistance | ★★☆☆☆ | ★★★★★ | ★★★☆☆ |

Winner: PETG (overall stability with minimal downsides).

Note: Nylon is durable but moisture-sensitive.

5.3 Printing Difficulty

| Property | Nylon | PETG | ABS |

| Warping risk | Medium | Low | High |

| Printing temperature | High | Medium | High |

| Need for enclosure | Recommended | Not needed | Mandatory |

| Moisture control | Essential | Low | Medium |

Winner: PETG (easiest).

Most challenging: ABS.

5.4 Cost and Availability

- PETG: Widely available, affordable

- ABS: Also common and inexpensive

- Nylon: Usually higher cost, especially PA12 and specialty blends

Winner: PETG for best price-to-performance.

6. Which Material Should You Choose?

Your choice depends on your priorities:

Choose Nylon if you need:

- Maximum strength and toughness

- Moving mechanical parts

- High abrasion resistance

- Industrial-grade performance

Choose PETG if you need:

- A balance of strength, flexibility, and printability

- Outdoor durability

- Low warping and frustration-free printing

- Moderate mechanical performance with high reliability

Choose ABS if you need:

- Strong heat resistance

- Good impact strength

- Professional-quality prototypes

- Parts used indoors under load

No single material wins in all categories. Instead, each excels in specific applications.

7. Real-World Use Cases: Which Material Performs Best?

7.1 Gears and Moving Components

Best: Nylon

Absorbs impact, resists wear, and handles fatigue well.

7.2 Outdoor Parts

Best: PETG

Superior UV resistance and minimal moisture expansion.

7.3 High-Temperature Applications

Best: ABS

Stable in heated environments (car interiors, appliances).

7.4 Functional Prototypes

Best: PETG or ABS

PETG for durability, ABS for thermal stability.

7.5 Tooling and Jigs

Best: Nylon

Handles repeated load cycles and abrasion.

8. Long-Term Performance and Aging

Nylon Aging

- Moisture absorption can reduce performance if not dried

- Extremely long-lasting once printed and stabilized

- Withstands mechanical wear better than almost all other FDM filaments

PETG Aging

- Excellent stability over time

- UV and chemical-resistant

- No brittleness as it ages

ABS Aging

- Can become brittle with long-term UV exposure

- Maintains heat resistance reliably

- Good dimensional stability indoors

PETG offers the best long-term reliability for the average user, while Nylon dominates specialized mechanical applications.

9. FAQs: Nylon vs. PETG vs. ABS

Q1: Which material is strongest overall?

Nylon is the strongest, offering exceptional tensile strength, toughness, and fatigue resistance.

Q2: Which material is easiest to print?

PETG. It prints with minimal warping, bonds strongly between layers, and works well without an enclosure.

Q3: Which material is best for outdoors?

PETG. It resists UV, moisture, and weathering better than ABS and is more stable than Nylon outdoors.

Q4: Does Nylon always need drying before printing?

Yes. Nylon absorbs moisture quickly, and printing it wet leads to poor layer adhesion and surface defects.

Q5: Is ABS still worth using today?

Absolutely. ABS remains a professional standard for parts requiring heat resistance and mechanical reliability—if you have the equipment to print it properly.

Q6: Which filament gives the best surface finish?

PETG offers a glossy, clean finish with minimal post-processing. ABS sands well but requires effort to print without defects.

Q7: Which material is most cost-effective for strong prints?

PETG delivers the best price-to-performance ratio for general use.

Q8: Which material should beginners use for durable parts?

PETG. It’s forgiving while still offering strong, reliable mechanical performance.

10. Final Verdict

Nylon, PETG, and ABS each offer a unique blend of strength, durability, and practicality for 3D printing. No single filament is the “best” for every situation, but:

- Nylon is best for high-strength, load-bearing, and mechanically demanding applications.

- PETG is best for general-purpose durable printing and outdoor reliability.

- ABS is best when heat resistance and industrial prototyping are top priorities.

For most users seeking durable, high-strength parts with the fewest printing headaches, PETG is the ideal starting point.

For engineers and advanced users who require maximum performance, Nylon remains the gold standard.

For controlled environments requiring heat stability, ABS holds its ground as a dependable choice.

Choosing the right material means understanding not just strength and durability, but how each filament behaves during printing and over time. By matching your application’s requirements with the mechanical and environmental strengths of Nylon, PETG, or ABS, you’ll ensure successful, reliable 3D prints—whether for hobby projects, industrial prototypes, or end-use parts.