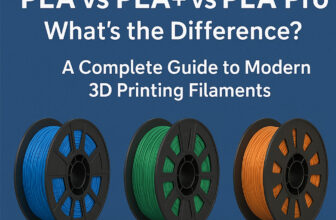

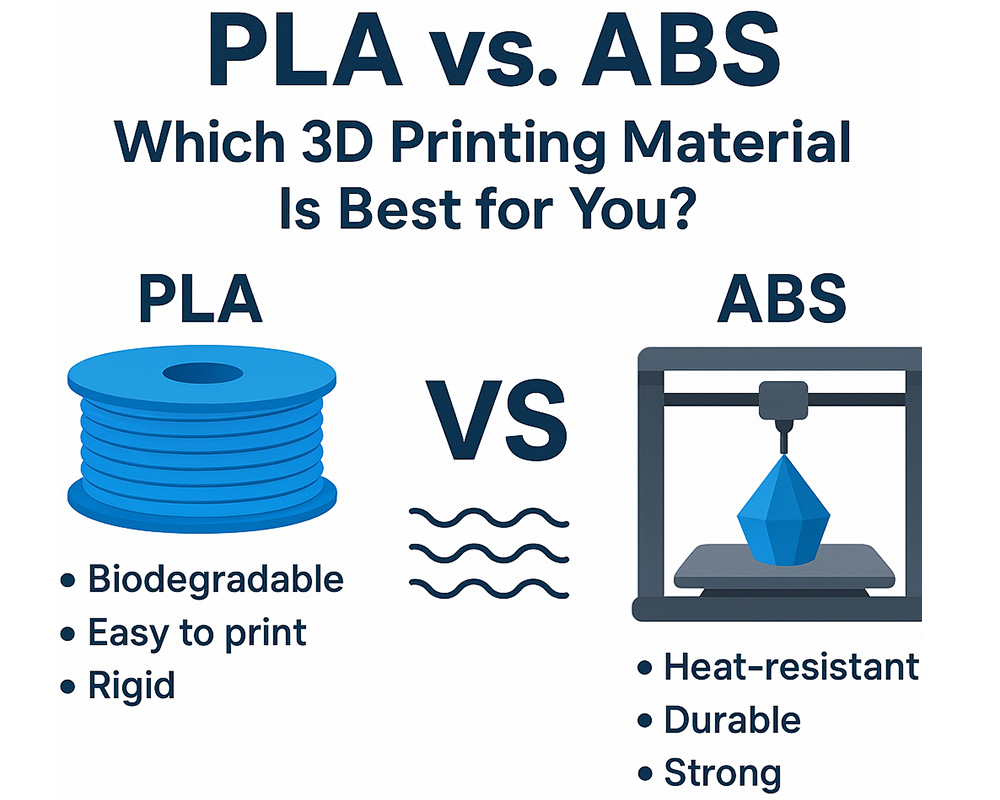

In the world of desktop FDM (Fused Deposition Modeling) 3D printing, few material debates have lasted as long—and remained as relevant—as PLA vs. ABS. These two thermoplastics have shaped the modern hobbyist and professional 3D-printing landscape, offering unique mechanical properties, strengths, weaknesses, and ideal use cases. Whether you’re designing functional prototypes, engineering components for daily use, or simply creating detailed decorative models, choosing the right filament is essential.

While the market has expanded to include PETG, TPU, nylon, PC blends, and carbon-fiber composites, PLA and ABS remain the fundamental starting point for most users. Their characteristics set the benchmark for printability, strength, durability, cost efficiency, and environmental impact. That’s why understanding the differences between the two is critical—not only for print success but for ensuring your final part performs the way you expect.

This guide explores PLA and ABS in comprehensive detail. We’ll discuss their mechanical properties, print behavior, environmental considerations, cost factors, post-processing techniques, and ideal applications. By the end, you will know exactly which material fits your needs, your printer’s capabilities, and your project’s requirements.

1. Understanding the Basics: What Are PLA and ABS?

Before comparing them, it’s important to understand the fundamentals of each material—their composition, how they behave when printed, and why they’re so widely used.

1.1 PLA (Polylactic Acid)

PLA is a biodegradable thermoplastic derived from renewable resources such as corn starch, sugarcane, or tapioca roots. It’s one of the most popular materials used in home and educational 3D printing due to its exceptional ease of use and smooth printing characteristics.

PLA melts at relatively low temperatures and has minimal warping, making it suitable for virtually all FDM printers, including low-cost beginner models.

To understand it more deeply, see: What Is 3D Printer Filament PLA?

Key characteristics of PLA:

- Low printing temperature (typically 190–220°C)

- Minimal warping and shrinkage

- Great for detailed, aesthetic prints

- Brittle compared to other engineering filaments

- Environmentally more sustainable

PLA is the go-to filament for prototyping, learning, and artistic applications.

1.2 ABS (Acrylonitrile Butadiene Styrene)

ABS is a petroleum-based thermoplastic used extensively in industrial manufacturing. It’s the same material used for LEGO bricks, car interiors, household appliances, and consumer electronics casings.

ABS is valued for its toughness, impact resistance, and heat tolerance. However, it’s more challenging to print than PLA because it requires specific environmental conditions to avoid cracking or warping.

To explore it further, see: What Is 3D Printer Filament ABS?

Key characteristics of ABS:

- Higher printing temperature (220–260°C)

- Requires controlled heat (heated bed and ideally an enclosure)

- Excellent impact resistance

- Greater heat resistance than PLA

- Strong fumes—proper ventilation recommended

ABS is the preferred choice for functional, load-bearing, and outdoor-exposed components.

2. Comparing PLA vs. ABS: A Technical Breakdown

To understand which filament suits you best, we must evaluate how each performs from a mechanical, chemical, and practical printing perspective.

Below is a detailed comparison of their key attributes.

2.1 Printability

PLA:

PLA is famously easy to print. Its low melting point and low thermal contraction make it incredibly forgiving, even for newcomers.

- Prints well without enclosure

- Consistent extrusion

- Minimal warping

- Good for small and large prints alike

ABS:

ABS demands more controlled conditions.

- Requires heated bed (90–110°C)

- Best printed in an enclosure to maintain ambient temperature

- Susceptible to layer separation and warping

- Can emit unpleasant fumes

Verdict:

PLA wins in printability. If reliability is your priority—or if you’re new to 3D printing—PLA is the safer option.

2.2 Mechanical Strength

Both materials offer solid mechanical performance, but in different ways.

PLA Strength Characteristics

- High tensile strength

- Very rigid

- Brittle under impact

- Prone to cracking under load or bending

PLA’s stiffness makes it suitable for parts needing dimensional precision, but it is not ideal for components under repeated stress.

ABS Strength Characteristics

- Excellent impact resistance

- More flexible than PLA

- Withstands mechanical stress better

- Better suited for snap-fit parts and mechanical assemblies

Verdict:

ABS is the better choice for functional and load-bearing components.

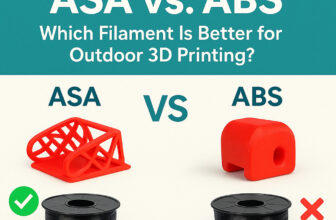

2.3 Heat Resistance

Heat tolerance is a major difference between these two filaments.

PLA Heat Resistance

- Softens around 55–60°C

- Deforms in hot environments

- Unsuitable for outdoor or high-temperature applications

ABS Heat Resistance

- Softens around 95–110°C

- Performs well under elevated temperatures

- Ideal for automotive and electrical components

Verdict:

ABS clearly outperforms PLA in heat resistance.

2.4 Environmental Impact

PLA is often chosen for its eco-friendly characteristics.

PLA Environmental Profile

- Derived from renewable resources

- Biodegradable under industrial composting conditions

- Emits fewer VOCs when printing

ABS Environmental Profile

- Petroleum-based

- Non-biodegradable

- Emits stronger fumes during printing

Verdict:

PLA is far more environmentally sustainable.

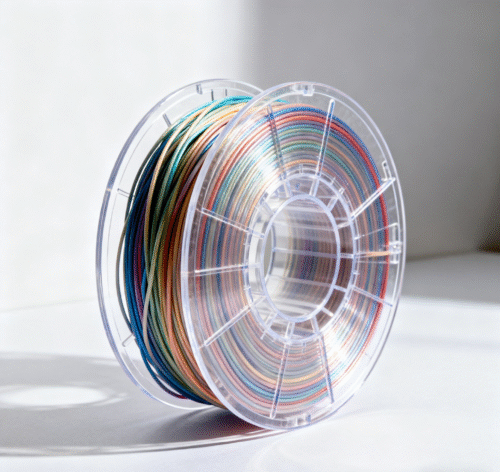

2.5 Aesthetic and Surface Finish

Both filaments can produce clean surface finishes, but PLA tends to be more consistent.

PLA Finish

- Smooth, glossy surface

- Excellent for detailed models

- Wide color and material options (silk PLA, matte PLA, wood-filled PLA, etc.)

ABS Finish

- Slightly matte surface

- More industrial feel

- Can be vapor-smoothed with acetone

Verdict:

PLA is best for decorative or visually refined prints, while ABS excels when durability trumps aesthetics.

2.6 Durability Over Time

Durability depends on environmental exposure, mechanical stress, and UV resistance.

PLA Long-Term Performance

- May degrade when exposed to sunlight

- Can become brittle over time

- Sensitive to heat

- Good for indoor, low-stress applications

ABS Long-Term Performance

- UV-resistant with additives

- Holds up to vibration, bending, and impact

- Stands up to daily wear and tear

- Ideal for engineering applications

Verdict:

ABS lasts longer in demanding environments.

3. Ideal Use Cases: When to Choose PLA or ABS

Selecting the right material depends on what you’re printing. Below are practical scenarios to help you decide.

3.1 When to Choose PLA

PLA is ideal for:

- Educational or beginner projects

- Rapid prototyping

- Aesthetic or decorative pieces (figurines, sculptures, models)

- Architectural models

- Cosplay accessories

- Detailed or complex shapes

- Low-stress mechanical parts

- Indoor-use household items

PLA excels where precision and visual quality are most important.

3.2 When to Choose ABS

ABS is ideal for:

- Functional prototypes

- Mechanical parts (gears, brackets, joints)

- Automotive components

- Electrical housings

- Toys and gadgets

- Tool components

- Outdoor or heat-exposed parts

- Snap-fit enclosures

ABS is the right choice when strength, heat resistance, and durability are critical.

4. Technical Specifications Comparison

Below is a deeper engineering breakdown of PLA and ABS characteristics.

Property | PLA | ABS |

| Printing Temperature | 190–220°C | 220–260°C |

| Bed Temperature | 20–60°C | 90–110°C |

| Print Difficulty | Easy | Medium–Hard |

| Strength | High tensile strength | High impact strength |

| Flexibility | Low | Moderate |

| Heat Resistance | Poor | Excellent |

| Environmental Impact | Eco-friendly | Petroleum-based |

| Odor During Print | Low | Moderate–High |

| Warping | Minimal | Significant without enclosure |

| Surface Finish | Smooth and glossy | Matte and industrial |

| Post-Processing | Sanding, painting | Acetone smoothing, sanding, painting |

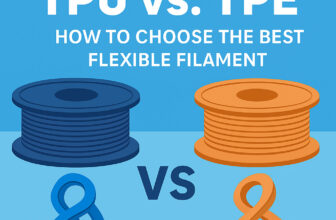

5. Printing Requirements and Best Practices

For success with each filament, follow these guidelines.

5.1 PLA Printing Tips

- Extruder temperature: 190–210°C

- Bed temperature: 20–60°C (optional)

- Cooling fan: 100% after first layer

- Printing speed: 40–70 mm/s

- Avoid enclosure: PLA performs better with airflow

Best practices:

- Store PLA in dry conditions to prevent brittleness

- Use a filament dryer if moisture is absorbed

- Use painter’s tape, PEI, or glue stick for bed adhesion

5.2 ABS Printing Tips

- Extruder temperature: 230–250°C

- Bed temperature: 90–110°C

- Cooling fan: Off or very low

- Enclosure: Highly recommended

- Ventilation: Required due to fumes

Best practices:

- Print in a warm environment to reduce warping

- Use ABS slurry or PEI for better bed adhesion

- Consider printing with an enclosure heater if available

- Keep airflow stable during the entire print

6. Post-Processing Comparison

Post-processing is often overlooked but plays a major role in how your final part looks and feels.

6.1 PLA Post-Processing

PLA can be:

- Sanded

- Primed and painted

- Glued with superglue

- Smoothed with heat gun (with caution)

- Polished using wet sanding

However, PLA cannot be chemically smoothed in the same way as ABS.

6.2 ABS Post-Processing

ABS is extremely post-production-friendly.

Acetone Vapor Smoothing

One of ABS’s biggest advantages is the ability to smooth surfaces using acetone vapor, producing a glossy, injection-molded appearance.

Additional Options:

- Sanding

- Drilling, tapping, machining

- Painting

- Heat treatment

ABS’s machinability makes it ideal for functional prototypes.

7. Environmental Stability: Indoor vs. Outdoor Use

PLA is best for indoor projects due to its sensitivity to heat and UV exposure. Over time, sunlight can cause PLA to become brittle and lose color.

ABS, on the other hand, performs better outdoors or in high-temperature environments. While ABS may degrade under prolonged UV exposure, UV-resistant ABS blends or coatings can address this issue.

8. Cost Comparison

Cost is often a deciding factor for hobbyists.

- PLA: Generally cheaper due to less complex production and high availability

- ABS: Slightly more expensive but still very affordable

The price difference is typically small, so your choice should be driven by material performance, not cost alone.

9. Which Material Is Best for You? Final Recommendations

Choose PLA if:

- You’re a beginner

- You need high-detail, aesthetic prints

- You want reliable, warp-free printing

- You prefer an eco-friendly material

- Your part will experience minimal stress or heat

Choose ABS if:

- You need durability and toughness

- Your part will undergo mechanical stress

- Heat resistance matters

- You’re willing to use an enclosure and proper ventilation

- You need parts for engineering or industrial use

There is no universal “best” material—only the best filament for your specific project.

10. FAQs

1. Is PLA or ABS better for beginners?

PLA is far better for beginners. It prints smoothly, has low warping tendencies, and doesn’t require an enclosure or high temperatures.

2. Is ABS stronger than PLA?

ABS has better impact resistance and flexibility, while PLA has higher tensile strength but is more brittle. For functional parts, ABS is generally superior.

3. Can PLA be used outdoors?

PLA can be used outdoors temporarily but may degrade due to heat and UV exposure. ABS performs better outdoors.

4. Can you print ABS without an enclosure?

Technically yes, but results will be inconsistent. An enclosure significantly reduces warping and layer separation.

5. Are PLA and ABS food-safe?

Neither is officially rated food-safe due to potential contaminants and micro-grooves in 3D-printed surfaces. Use caution.

6. Can you recycle PLA and ABS?

PLA is biodegradable in industrial facilities, while ABS is recyclable in certain plastic processing centers. Always check local regulations.

7. Which filament is more eco-friendly?

PLA is more environmentally sustainable due to its plant-based origins and lower carbon footprint.

8. Can I acetone-smooth PLA?

No. PLA is not soluble in acetone. ABS can be smoothed with acetone vapor.

9. What printers can handle ABS?

Most mid-range printers with a heated bed and enclosure can print ABS. PLA, however, can be printed on virtually any FDM machine.

10. Is there a material that combines the strengths of PLA and ABS?

Yes—PETG is often considered a balanced middle ground, offering ease of printing closer to PLA with durability approaching ABS.

Conclusion

Choosing between PLA and ABS comes down to your project type, environmental conditions, and printing expertise. PLA offers unmatched ease, beautiful surface finishes, and eco-friendly properties—perfect for prototypes, visual models, and hobby projects. ABS brings strength, durability, and heat resistance, making it ideal for demanding, functional parts that must perform reliably over time.

Understanding What Is 3D Printer Filament PLA? and What Is 3D Printer Filament ABS? is the foundation of mastering FDM 3D printing. With the insights in this guide, you’re now well-equipped to select the right material for your needs and achieve professional-quality results in every print.