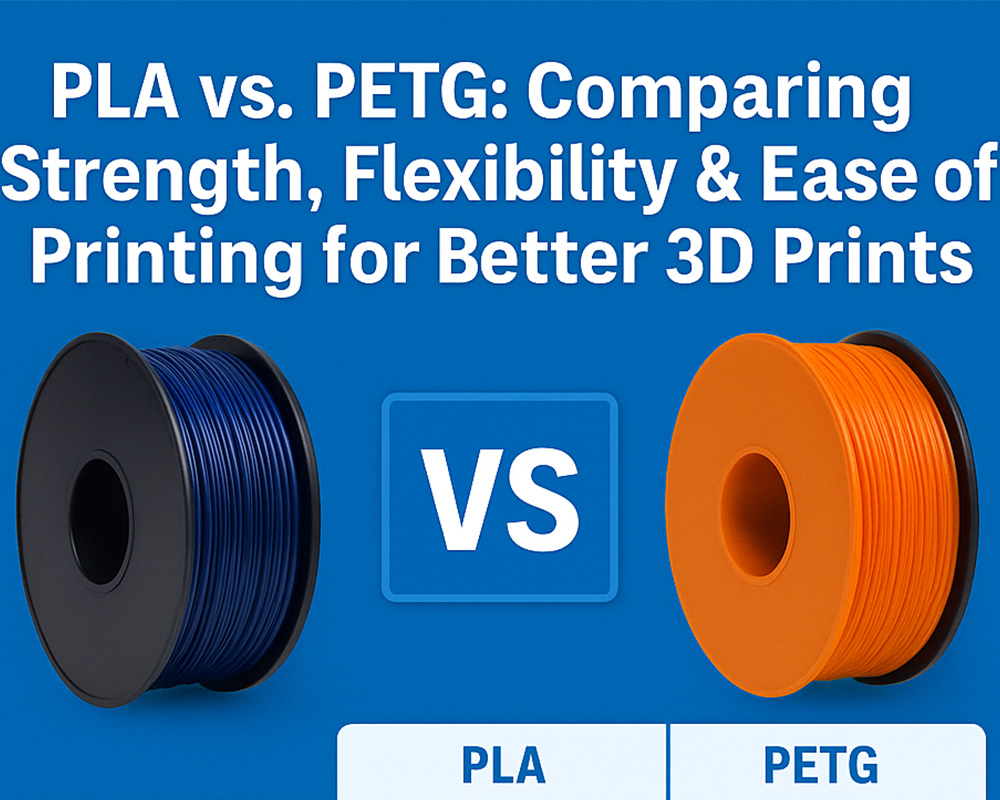

Choosing the right filament is one of the most foundational decisions in 3D printing—one that determines not only the outcome of a single print but also the capabilities of your entire workflow. Among hobbyists, educators, product designers, engineers, and professional prototyping labs, two filaments dominate discussions: PLA and PETG.

Both materials are widely available, deeply versatile, and suitable for a broad range of printers. Yet they behave differently in practice, and each has strengths and limitations that can affect the durability, surface quality, dimensional accuracy, and overall reliability of the final product. Whether you’re printing mechanical components, household objects, functional prototypes, aesthetic models, or even small-batch manufacturing runs, understanding how PLA and PETG compare in strength, flexibility, and printability is essential.

This comprehensive guide explores PLA vs. PETG across their mechanical performance, ease of printing, environmental characteristics, post-processing behavior, and real-world use cases. It is designed to help you make a confident decision based on deep technical insight rather than surface-level generalizations.

If you’re exploring additional comparisons, you may also find this useful: See related articles: PLA vs. ABS.

Table of Contents

- Introduction

- Understanding PLA

- Understanding PETG

- PLA vs. PETG: Strength Compared

- PLA vs. PETG: Flexibility Compared

- PLA vs. PETG: Ease of Printing Compared

- Other Key Differences

- Use-Case Comparisons

- Cost Considerations

- Environmental Impact and Sustainability

- Practical Tips for Choosing Between PLA and PETG

- Final Verdict

- Frequently Asked Questions (FAQ)

1. Introduction

As additive manufacturing becomes increasingly accessible, the choice of filament material plays a decisive role in determining print success and long-term performance. PLA and PETG remain the two most commonly recommended materials for users of all skill levels, but their behavior differs more subtly than many assume.

PLA is often presented as the easiest printing material and the ideal choice for beginners. That reputation is largely deserved: its low printing temperature, predictable shrinkage, excellent detail reproduction, and minimal warping make it highly reliable for everyday prints.

PETG, meanwhile, is often described as the “next step after PLA”—combining ease of printing with durability closer to ABS. Yet PETG introduces its own intricacies, such as stringing, oozing, and more demanding extrusion settings.

Understanding how each material behaves mechanically, thermally, and chemically can help you determine which is ideal for your applications.

This article provides a professional, engineering-level comparison while remaining accessible to hobbyists and newcomers.

2. Understanding PLA

What PLA Is

PLA (Polylactic Acid) is a biopolymer derived primarily from renewable sources such as corn starch, cassava, and sugarcane. It is one of the most widely used plastics in additive manufacturing due to its low melting temperature and environmentally friendly origins.

PLA filaments is naturally rigid and dimensionally stable, making it well suited to applications where visual accuracy and surface finish matter more than impact resistance or high thermal performance.

Key Characteristics

- Low printing temperatures

- Low warping

- High stiffness

- Brittle behavior under impact

- Not ideal for outdoor environments

- Biodegradable under industrial composting conditions

Mechanical Properties of PLA

PLA exhibits mechanical stiffness that rivals or exceeds many engineering plastics. However, high stiffness comes at the cost of brittleness.

Property | Typical PLA Performance |

| Tensile Strength | High |

| Impact Resistance | Low |

| Flexibility | Low |

| Stiffness | Very High |

| Layer Adhesion | Good |

| Heat Resistance | Low |

PLA is excellent for prints requiring precision and rigidity, such as jigs, decorative objects, housings, architectural models, or educational builds. It is less suited for load-bearing or impact-prone applications.

Printing Characteristics of PLA

PLA’s forgiving nature stems from its predictable behavior during extrusion.

Advantages in Printing

- Low extrusion temperature (190–215°C)

- Moderate bed temperature (0–60°C)

- Minimal warping

- Excellent bridging and overhang performance

- Smooth detail reproduction

Because PLA is thermally stable in the molten state, it cools predictably and rarely shrinks enough to cause dimensional issues.

Common Challenges

While PLA is easy overall, it does have constraints:

- Susceptible to heat deformation above ~55°C

- Can become brittle over time

- Moisture-sensitive (absorbs humidity)

- Prone to clogging in all-metal hotends if overheated

Pros and Cons of PLA

PLA remains the “default” material for many because of its predictability, but it is not a one-size-fits-all solution.

3. Understanding PETG

What PETG Is

PETG (Polyethylene Terephthalate Glycol-modified) is a glycol-modified form of the same plastic used in beverage bottles. The modification enhances toughness, clarity, and structural reliability. PETG filaments bridges the gap between PLA and ABS, offering good printability with significantly better durability.

Key Characteristics

- Flexibility and impact resistance

- Strong layer adhesion

- High durability

- Low warping

- Moisture-sensitive

- Requires accurate temperature tuning

PETG is designed for functional components, mechanical assemblies, and real-world use where PLA simply does not hold up.

Mechanical Properties of PETG

| Property | Typical PETG Performance |

| Tensile Strength | Moderate–High |

| Impact Resistance | High |

| Flexibility | Medium |

| Stiffness | Moderate |

| Layer Adhesion | Excellent |

| Heat Resistance | Medium |

PETG is stronger than PLA in many real-world conditions because it resists cracking under stress and maintains integrity under mechanical load.

Printing Characteristics of PETG

Advantages in Printing

- Good bridging with proper tuning

- Low warping relative to ABS

- Excellent adhesion between layers

- Higher temperature resistance than PLA

PETG generally prints within:

- Extruder temperature: 230–250°C

- Bed temperature: 70–90°C

Such temperatures require more stable printers and better cooling management.

Challenges

PETG is more temperamental than PLA:

- Tends to string and ooze without tuned retraction

- Can stick too aggressively to build surfaces

- Requires moderate print speeds

- Sensitive to moisture absorption

Still, PETG remains far easier to print than most engineering filaments.

Pros and Cons of PETG

PETG is ideal for tougher, long-lasting prints where performance matters.

4. PLA vs. PETG: Strength Compared

Strength in 3D printing includes tensile strength, impact strength, fatigue resistance, and real-world durability. While PLA often tests higher in raw tensile strength, the brittle nature of PLA means that PETG typically performs better under real mechanical stress.

Tensile Strength

- PLA: Higher nominal tensile strength

- PETG: Slightly lower raw tensile strength

Yet PLA cracks more easily under sudden load.

Impact Strength

- PLA: Low

- PETG: High

If you need shock resistance, PETG is the clear winner.

Layer Adhesion

- PLA: Good

- PETG: Excellent

PETG parts behave more like single solid pieces due to superior interlayer bonding.

Durability Over Time

PETG remains stable for years in typical environments. PLA can degrade, especially with exposure to heat, UV, or humidity.

Winner:PETG, for most functional or load-bearing parts.

5. PLA vs. PETG: Flexibility Compared

Flexibility determines how well a material bends under stress without cracking.

- PLA: Stiff, rigid, prone to snapping

- PETG: Semi-flexible, capable of bending under load

PETG’s flexibility makes it suitable for clips, brackets, enclosures, toys, and functional parts requiring some give.

Winner:PETG

6. PLA vs. PETG: Ease of Printing Compared

Ease of printing is one of the main reasons many users stick with PLA. PETG is manageable but requires more precision.

PLA Printing Ease

- Beginner-friendly

- No enclosure required

- Minimal tuning

- Excellent print success rate

- Handles overhangs well

PETG Printing Ease

- Requires tuning of retraction, speed, and cooling

- Oozes more easily

- Sensitive to filament moisture

- May adhere too strongly to smooth glass beds

- Slight warping possible

Winner:PLA, by a wide margin.

7. Other Key Differences

Durability and Longevity

PETG is more resistant to aging, humidity, and moderate temperatures. PLA can get brittle over time.

Environmental Resistance

UV Resistance

- PLA: Poor

- PETG: Better

Chemical Resistance

- PLA: Low

- PETG: Moderate–High

Thermal Resistance

PETG withstands ~70–80°C before deforming; PLA softens around 55°C.

Aesthetic Finish

- PLA prints very smooth, with crisp edges.

- PETG often shows stringing and a slightly glossy, “soft” surface texture.

Post-Processing

- PLA sands and paints easily.

- PETG is harder to sand and may gum up.

Food-Safe Considerations

Although raw PETG is used in bottles, most 3D printed objects (both PLA and PETG) are not food-safe due to bacterial crevices and printer contaminants.

8. Use-Case Comparisons

Best Uses for PLA

- Decorative objects

- Prototypes

- Replacement parts with low stress

- Educational and hobby prints

- Detailed figurines

- Architectural models

- Low-temperature applications

Best Uses for PETG

- Mechanical parts

- Functional end-use components

- Outdoor applications

- Brackets, clamps, and fixtures

- Electronics housings

- Parts exposed to moderate heat

- Wearable components

9. Cost Considerations

PLA is usually cheaper and more widely available. PETG costs slightly more but remains cost-effective given its superior durability.

Typical filament prices (varies by brand):

- PLA: $18–$28 per kg

- PETG: $20–$35 per kg

10. Environmental Impact and Sustainability

PLA is marketed as biodegradable, but in reality, it biodegrades only in specialized industrial composting conditions. Still, it remains a renewable-resource polymer.

PETG is petroleum-based but recyclable in some facilities (PET family, depending on glycol modification).

Neither material is fully sustainable, but PLA has the edge in renewability.

11. Practical Tips for Choosing Between PLA and PETG

Choose PLA if you:

- Want the easiest printing experience

- Need high detail and visual quality

- Are printing non-functional or low-stress parts

- Prefer renewable materials

Choose PETG if you:

- Need durability and impact resistance

- Are printing functional, mechanical components

- Plan to use prints outdoors

- Need moderate heat resistance

- Can manage more complex print tuning

12. Final Verdict

PLA vs. PETG is not a question of which material is “better”—it is a question of application.

- If you prioritize ease of printing, aesthetic quality, and precision, PLA remains unmatched among consumer filaments.

- If you prioritize durability, flexibility, heat resistance, and real-world mechanical performance, PETG is the superior choice.

As a practical guideline:

Start with PLA. Move to PETG when you need stronger, more functional prints.

And if you’re comparing additional materials, see this resource: See related articles: PLA vs. ABS.

13. Frequently Asked Questions (FAQ)

1. Is PETG stronger than PLA?

In real-world use, yes. While PLA may have higher tensile strength on paper, PETG’s flexibility and impact resistance make it stronger for functional parts.

2. Is PETG harder to print than PLA?

Yes. PLA is the easiest mainstream filament to print. PETG requires tuning but is still far easier than ABS filaments or nylon.

3. Can PLA be used outdoors?

Not for long. Sunlight and heat degrade PLA. PETG is much better suited for outdoor applications.

4. Is PETG food-safe?

Raw PETG can be food-safe, but 3D printing introduces microscopic crevices that harbor bacteria. Always assume printed PETG is not food-safe unless processed properly.

5. Which filament is better for beginners?

PLA. No contest—it is the most reliable starter material.

6. Does PETG warp like ABS?

No. PETG has low warping tendency and does not require an enclosure, though it prints best in stable ambient conditions.

7. Can you sand and paint PLA or PETG?

PLA is easy to sand and paint. PETG is more difficult due to its flexibility and surface characteristics.

8. Which filament is more heat-resistant?

PETG withstands higher temperatures than PLA, making it more suitable for functional parts.

9. Should I switch from PLA to PETG for stronger parts?

Yes, especially if you need durability, flexibility, or components that must handle mechanical loads.