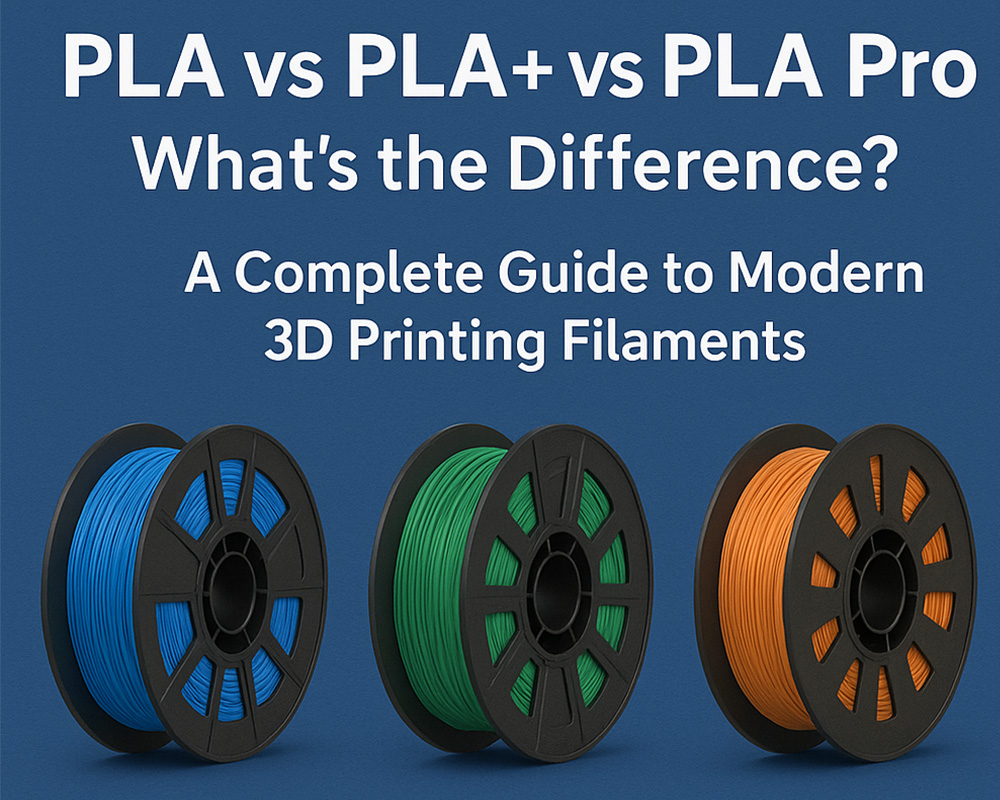

3D printing has evolved rapidly over the past decade, and with it, the variety of materials available to makers, engineers, educators, and manufacturers. Among these materials, PLA stands out as one of the most widely used due to its ease of printing, low warping, and environmentally friendly nature. But as demand for better mechanical performance has grown, manufacturers have developed enhanced versions of PLA—specifically PLA+ and PLA Pro.

Today, many users find themselves asking the same core question:

“What’s the actual difference between PLA+, PLA Pro, and Standard PLA?”

This guide provides a detailed, technical, and practical comparison of these materials, helping you choose the right filament depending on your goals, machinery, and application needs. Whether you print prototypes, functional end-use components, artistic models, or engineering parts, understanding these materials is crucial for achieving the best results.

Table of Contents

- Why Understanding PLA Variants Matters

- What Is Standard PLA?

- What Is PLA+?

- What Is PLA Pro?

- PLA vs PLA+ vs PLA Pro: Head-to-Head Comparison

- Applications: When to Use Which Material

- Practical Considerations When Choosing a PLA Variant

- Expert Tips for Printing Each Material

- Should You Anneal Your PLA, PLA+, or PLA Pro Prints?

- Environmental Impact and Safety Comparison

- Common Misconceptions About PLA, PLA+, and PLA Pro

- Which Should You Buy? A Final Recommendation

- Frequently Asked Questions (FAQs)

- Conclusion

1. Introduction: Why Understanding PLA Variants Matters

Polylactic Acid—more commonly known as PLA—remains the dominant filament for FDM/FFF 3D printing. While originally valued for its user-friendly behavior, the development of advanced PLA formulations such as PLA+ and PLA Pro has dramatically expanded its capabilities.

Today, PLA is no longer just a “beginner filament.” The enhanced versions offer:

- improved mechanical strength

- higher impact resistance

- better heat stability

- smoother print surfaces

- more predictable dimensional accuracy

- increased viability for functional applications

Despite these improvements, many users still default to standard PLA without knowing what stronger or more durable alternatives exist—or assuming PLA+ and PLA Pro are simply marketing gimmicks.

They aren’t.

While naming conventions vary between manufacturers, most PLA+ and PLA Pro filaments are formulated with special additives that significantly change material behavior. This article provides a clear and unbiased breakdown of these differences.

2. What Is Standard PLA?

Standard PLA is the most widely offered filament in the 3D printing world. Made from renewable plant-based materials such as corn starch or sugarcane, PLA is one of the easiest materials to print.

2.1 Composition of Standard PLA

Standard PLA is a biopolymer derived from lactic acid, typically produced through the fermentation of natural sugars. The key properties of PLA stem from its:

- crystallinity

- molecular weight

- thermal behavior

- biodegradability

Its structure produces a stiff, rigid plastic with low thermal resistance and limited ductility.

2.2 Mechanical Properties of Standard PLA

While values vary, typical ranges include:

- Tensile Strength: ~60 MPa

- Tensile Modulus: ~3.5 GPa

- Elongation at Break: 4–6%

- Impact Resistance: low

- Glass Transition Temperature: ~55–60°C

These numbers illustrate PLA’s inherent limitations:

- it can crack under stress

- it’s brittle and not good for impact loads

- it softens under moderate heat

- it may deform in a hot car or warm environment

However, its advantages remain substantial.

2.3 Advantages of Standard PLA

- very low printing temperature

- no enclosure needed

- minimal warping

- excellent surface finish

- biodegradable under industrial conditions

- ideal for beginners and rapid prototyping

- wide color availability

- low smell during printing

2.4 Limitations of Standard PLA

- can become brittle over time

- limited heat resistance

- not suitable for high-stress mechanical parts

- may struggle with snap-fits or functional hinges

- outdoor durability is limited

In short: PLA is ideal for visual models and light-duty prints, but struggles with functional components requiring strength or flexibility.

To understand it more deeply, see: What Is 3D Printer Filament PLA?

3. What Is PLA+?

The Popular Strengthened Upgrade**

As the demand for stronger consumer-grade filament grew, manufacturers introduced PLA+—a modified PLA designed to overcome common weaknesses of standard PLA.

PLA+ is not a standardized industry term; each brand uses slightly different formulas. However, most PLA+ filaments share common characteristics, such as:

- greater impact resistance

- improved ductility

- smoother surface finish

- better layer adhesion

- slightly improved heat resistance

- reduced brittleness

3.1 How PLA+ Is Formulated

PLA+ is essentially PLA blended with modifiers. These may include:

- biodegradable toughening agents

- polybutylene adipate terephthalate (PBAT)

- flexibilizers

- nucleating agents for crystallization

- impact modifiers

- small volumes of co-polymers

The purpose of these additives is to address the weaknesses of standard PLA without sacrificing its ease of printing.

3.2 Mechanical Properties of PLA+

Typical improvements include:

- Tensile Strength: similar or slightly higher than PLA (~60–65 MPa)

- Elongation at Break: 10–20% (much higher than PLA)

- Impact Resistance: moderate to high

- Heat Deflection Temperature: 60–65°C for many brands

In real-world terms, PLA+ performs better when prints must endure stress, bending, or accidental drops.

3.3 Advantages of PLA+

- reduced brittleness

- improved toughness and flexibility

- higher aesthetic quality in many cases

- less nozzle clogging compared to some other modified materials

- generally compatible with standard open-frame printers

- excellent for functional prototypes

- better tolerance for imperfect print environments

3.4 Limitations of PLA+

- typically costs more than standard PLA

- still not as heat-resistant as PETG or ABS

- some brands introduce slight stringing

- “PLA+” is not standardized, so quality varies

PLA+ is a solid all-purpose filament for most users who want durability and printability without adopting more demanding engineering materials.

4. What Is PLA Pro?

The Technically Advanced, Engineering-Focused PLA**

While PLA+ improves toughness and reliability, PLA Pro targets high-performance applications where greater strength, dimensional accuracy, or heat stability is needed.

PLA Pro is often considered:

- a premium, semi-engineering PLA

- a higher-crystallinity PLA blend

- a stronger and more temperature-resistant PLA variant

It typically offers performance that sits between PLA+ and PETG, sometimes surpassing PETG in stiffness and strength while maintaining PLA-like printability.

4.1 How PLA Pro Differs in Composition

Manufacturers may incorporate:

- high-crystallinity PLA grades

- advanced nucleating agents

- more refined impact modifiers

- chain extenders for molecular reinforcement

- engineering-grade toughening additives

These enhance mechanical performance without significantly complicating printing.

4.2 Mechanical Properties of PLA Pro

Typical ranges (brand-dependent):

- Tensile Strength: 65–75 MPa

- Elongation at Break: 15–40%

- Impact Resistance: high

- Heat Deflection Temperature (HDT): 65–80°C (sometimes higher after annealing)

PLA Pro often exceeds both PLA and PLA+ in:

- temperature tolerance

- dimensional accuracy

- mechanical durability

- load-bearing capability

4.3 Advantages of PLA Pro

- stronger than PLA and many PLA+ formulations

- better temperature stability

- superior dimensional accuracy for engineering parts

- excellent layer adhesion

- very good surface finish

- ideal for snap-fits and mechanical components

- potential for significantly improved performance when annealed

Many designers and prototypers choose PLA Pro when they want performance close to PETG without PETG’s printing challenges.

4.4 Limitations of PLA Pro

- more expensive than PLA and PLA+

- may require slightly higher print temperatures

- some brands require an enclosure for best dimensional stability

- may warp more than PLA+ due to higher crystallization

Nevertheless, PLA Pro remains one of the most capable PLA formulations available.

5. PLA vs PLA+ vs PLA Pro: Head-to-Head Comparison

Below is a detailed comparison across the most relevant performance categories.

5.1 Strength and Durability

| Property | Standard PLA | PLA+ | PLA Pro |

| Tensile Strength | Moderate | Moderate–High | High |

| Brittleness | High | Reduced | Low |

| Impact Resistance | Low | Moderate | High |

| Flexibility | Low | Medium | Medium–High |

| Layer Adhesion | Good | Improved | Excellent |

Summary:

PLA+ is noticeably tougher than PLA, while PLA Pro often delivers near-engineering-grade performance.

5.2 Printability

| Factor | Standard PLA | PLA+ | PLA Pro |

| Ease of Printing | Very Easy | Easy | Moderate |

| Temperature Sensitivity | Low | Low–Medium | Medium |

| Warping | Very Low | Low | Low–Medium |

| Nozzle Requirements | Standard Brass | Standard Brass | Brass or Hardened if abrasive additives exist |

Summary:

PLA remains the easiest, but PLA Pro is still far easier than PETG, ABS, or Nylon.

5.3 Heat Resistance

| Property | Standard PLA | PLA+ | PLA Pro |

| Heat Deflection Temperature | 55–60°C | 60–65°C | 65–80°C |

| Post-Annealing Effect | Moderate | Moderate–High | High |

Summary:

PLA Pro provides significantly better temperature stability, especially when annealed.

5.4 Surface Quality

PLA+ and PLA Pro often produce:

- smoother surfaces

- more consistent extrusion

- better color saturation

- reduced visible layer lines

Standard PLA is still excellent for aesthetics, but enhanced formulations often print cleaner.

5.5 Cost Comparison

| Material | Relative Cost |

| Standard PLA | Lowest |

| PLA+ | Slightly Higher |

| PLA Pro | Highest of the three |

The price difference is usually justified by the performance improvements.

6. Applications: When to Use Which Material

Here are the optimal use cases for each filament:

6.1 Best Uses for Standard PLA

- artistic models

- figurines

- decorations

- educational projects

- display prototypes

- low-stress enclosures

- low-temperature indoor parts

PLA excels when quality and ease of use matter more than mechanical durability.

6.2 Best Uses for PLA+

- functional prototypes

- parts subjected to moderate stress

- brackets and fixtures

- RC components

- cosplay props requiring durability

- tools with light duty cycles

- accessories and spare parts

PLA+ is ideal when the print must survive occasional bending or impact.

6.3 Best Uses for PLA Pro

- engineering prototypes

- mechanical components

- outdoor models (short-term use)

- parts requiring high stiffness

- structural fixtures

- assemblies with snap-fits

- load-bearing shells

- drone components

- parts benefiting from annealing

PLA Pro bridges the gap between PLA and PETG, offering higher performance without major printing challenges.

7. Practical Considerations When Choosing a PLA Variant

Before deciding which PLA filament to use, consider:

7.1 Printer Capabilities

- Does your printer reach 210–230°C? (Important for PLA+ and PLA Pro)

- Do you have a heated bed?

- Is an enclosure available? (Optional but helpful for PLA Pro)

- Nozzle material (abrasive PLA Pro blends may require hardened steel)

7.2 Intended Use

- Visual model? PLA

- Functional part? PLA+

- Load-bearing component? PLA Pro

- High-temperature environment? PLA Pro with annealing

7.3 Environmental Exposure

PLA is biodegradable under industrial composting conditions, but its degradation outdoors is slow. Still:

- PLA softens in a hot car

- PLA+ performs slightly better

- PLA Pro performs significantly better

For outdoor use, none of these outperform PETG or ASA, but PLA Pro is the most capable PLA variant.

7.4 Dimensional Accuracy

PLA Pro often provides the best precision due to its controlled formulation and crystallization behavior.

8. Expert Tips for Printing Each Material

8.1 Printing Standard PLA

- Nozzle: 190–210°C

- Bed: 20–60°C

- Cooling: 100%

- Speed: 40–80 mm/s

Tips:

- Keep drafts minimal for large parts

- Use a clean, cool bed to avoid elephant’s foot

- PLA prefers strong cooling; add a fan shroud if needed

8.2 Printing PLA+

- Nozzle: 200–220°C

- Bed: 50–70°C

- Cooling: 60–100%

- Speed: 40–70 mm/s

Tips:

- Slightly lower cooling may improve layer adhesion

- Increase temperature for strong parts

- Use a PEI sheet for reliable adhesion

8.3 Printing PLA Pro

- Nozzle: 210–230°C

- Bed: 55–70°C

- Cooling: 30–70%

- Speed: 35–60 mm/s

Tips:

- Use moderate cooling to avoid layer separation

- Print slower for engineering parts

- Consider annealing for top performance

9. Should You Anneal Your PLA, PLA+, or PLA Pro Prints?

Annealing changes the crystalline structure of PLA, improving:

- heat resistance

- stiffness

- dimensional stability

- overall strength (depending on formulation)

Annealing Temperatures

- 80–110°C depending on the brand

- Use an oven with precise temperature control

Impact on Materials

- Standard PLA: strength may increase, but warping risk is high

- PLA+: better results; improved heat performance

- PLA Pro: best improvement; often produces near-PETG or ABS-level heat resistance

If heat resistance is important, choosing PLA Pro and annealing it can be transformative.

10. Environmental Impact and Safety Comparison

All three materials share common traits:

- Made primarily from renewable resources

- Low emissions compared to ABS or Nylon

- Odorless or mild smell

- Safe for indoor printing with proper ventilation

However:

- Enhanced additives in PLA+ and PLA Pro reduce biodegradability

- They are still more eco-friendly than fossil-based plastics

- For educational or home environments, all remain excellent choices.

11. Common Misconceptions About PLA, PLA+, and PLA Pro

Misconception 1: PLA+ is simply PLA with more pigment

False. Nearly all PLA+ filaments include impact modifiers or co-polymers.

Misconception 2: PLA Pro is just marketing jargon

False. High-crystallinity PLA formulations offer genuine performance improvements.

Misconception 3: PLA cannot be used for functional parts

Partially false. PLA+ and PLA Pro dramatically expand PLA’s functional use-case potential.

Misconception 4: PLA+ and PLA Pro can replace PETG or ABS completely

Not always. For high heat environments, PETG, ASA, or ABS still perform better.

12. Which Should You Buy? A Final Recommendation

Choose Standard PLA if you want:

- easiest printing experience

- low cost

- models or decorative items

Choose PLA+ if you want:

- greater strength and toughness

- better layer adhesion

- versatile printing with minimal effort

Choose PLA Pro if you want:

- maximum performance within the PLA family

- improved heat resistance

- more robust and dimensionally stable parts

- prints suitable for engineering or semi-functional use

13. Frequently Asked Questions (FAQs)

1. Is PLA+ stronger than PLA?

Yes. Most PLA+ filaments are significantly tougher and less brittle than standard PLA.

2. Is PLA Pro better than PLA+?

For most mechanical applications, yes. PLA Pro generally provides higher heat resistance, better durability, and superior layer adhesion.

3. Will PLA, PLA+, or PLA Pro degrade over time?

Indoors, degradation is minimal. Outdoors, UV and heat can cause slow weakening, but PLA Pro performs best.

4. Can PLA+ be used in a car interior?

Sometimes, but results vary. PLA Pro or PETG is more suitable due to higher heat tolerance.

5. Is PLA Pro suitable for food-contact items?

Only if specifically labeled as food-safe by the manufacturer, and the printer hardware is also food-safe.

6. Do PLA+ and PLA Pro require special nozzles?

Usually not, unless they contain abrasive additives (check your brand’s documentation).

7. Is annealing necessary for PLA Pro?

Not required, but it can significantly improve heat resistance and dimensional stability.

8. Which material is best for miniatures?

Standard PLA or PLA+ depending on desired durability.

9. Can PLA Pro replace PETG?

In many cases, yes—especially for rigid, load-bearing parts. But PETG still performs better in high-temperature or outdoor environments.

10. Which material gives the best surface finish?

PLA+ and PLA Pro typically produce smoother and more consistent surfaces than standard PLA.

Conclusion

Standard PLA, PLA+, and PLA Pro all have their place in modern 3D printing, each offering distinct strengths:

- PLA is perfect for easy, high-quality prints and decorative projects.

- PLA+ provides upgraded toughness and reliability for everyday functional use.

- PLA Pro delivers semi-engineering performance while maintaining PLA’s printability.

Understanding these differences allows you to choose the ideal filament for your design requirements—whether you’re printing art, prototypes, mechanical components, or high-strength functional parts.