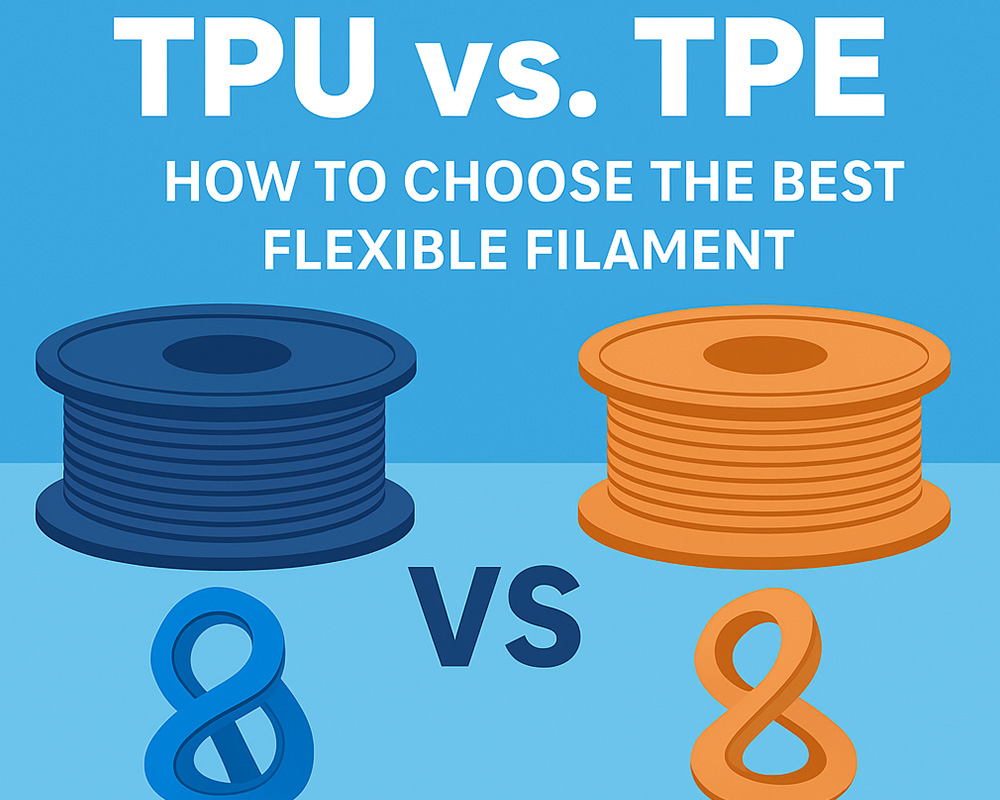

Flexible 3D printing materials have become indispensable in product development, functional prototyping, and consumer goods manufacturing. Whether you’re printing phone cases, vibration-damping components, wearable prototypes, or soft-touch grips, choosing the right flexible filament can significantly impact the performance and printability of your final product.

Two materials dominate the space: TPU (Thermoplastic Polyurethane) and TPE (Thermoplastic Elastomer). Both offer rubber-like flexibility, impact resistance, and impressive durability, but they behave differently—both inside the printer and in real-world applications.

If you’re wondering “TPU vs. TPE: which flexible filament should I choose?”, this comprehensive guide covers everything you need to know, from material science fundamentals to application-specific recommendations.

This article provides an engineer-level breakdown, practical printing considerations, and design insights to help you make the right choice for your next project.

Table of Contents

- Introduction to Flexible 3D Printing Filaments

- Understanding Material Foundations

- Mechanical Properties Comparison

- Printability Comparison

- Application-Specific Insights

- Choosing the Right Shore Hardness

- Design Considerations for Flexible Filaments

- Cost and Availability

- Which Should You Choose? A Scenario-Based Guide

- FAQs about TPU vs. TPE

1. Introduction to Flexible 3D Printing Filaments

Flexible materials have transformed what’s possible with consumer-grade and industrial 3D printers. Unlike rigid plastics such as PLA or ABS, flexible filaments bend, compress, and stretch without snapping. This makes them ideal for functional prototypes, wearable components, soft robotics, and vibration-damping assemblies.

Among flexible filaments, TPU and TPE are by far the most widely used. Although they share similarities, their differences become crucial depending on your design intent:

- Do you need high elasticity?

- Do you need chemical resistance?

- Do you need better printability?

- Do you need precise tolerances?

Understanding the material characteristics of TPU and TPE helps ensure your application performs exactly as intended.

2. Understanding Material Foundations

What Is TPU?

TPU (Thermoplastic Polyurethane) is a type of thermoplastic elastomer known for its outstanding abrasion resistance, impact toughness, and elastic recovery.

Key characteristics include:

- Rubber-like flexibility

- High tear strength

- Strong resistance to oil, grease, and many chemicals

- Excellent wear resistance

- High elasticity with reliable shape recovery

In the 3D printing world, TPU has become the gold standard for flexible functional parts because it provides a balanced combination of strength, durability, and printability.

To understand it more deeply, see: What Is 3D Printer Filament TPU?

What Is TPE?

TPE (Thermoplastic Elastomer) is a broader class of flexible polymers, often softer and more elastic than TPU. TPE materials are blends that combine the properties of rubber with the convenience of thermoplastics.

Notable traits include:

- Very high flexibility and softness

- Superior compression characteristics

- Extremely elastic, often more than TPU

- Excellent suitability for soft-touch components

TPEs are produced in many formulations, each with slightly different properties. Some are extremely soft and gel-like; others more rubber-like. This diversity can be beneficial but can complicate material selection.

To understand it more deeply, see: What Is 3D Printer Filament TPE?

3. Mechanical Properties Comparison

Understanding the mechanical properties is essential because flexibility is only part of the story. Your application may require abrasion resistance, rebound recovery, or resistance to tearing and deformation.

Below is a professional comparison of TPU and TPE across critical functional categories.

Flexibility

- TPU: Flexible but typically firmer; good balance of rigidity and flexibility.

- TPE: Usually softer and more pliable; often preferred when very soft or stretchy parts are needed.

In terms of Shore hardness, TPU generally ranges from 85A to 95A, whereas TPE options span from 70A down to extremely soft gel-like grades.

Elasticity & Recovery

- TPU: Excellent elasticity and strong recovery; returns to original shape even after repeated deformation.

- TPE: Extremely elastic but may exhibit slower recovery, depending on formulation.

TPU’s ability to rebound makes it ideal for vibration dampers, hinges, and components exposed to repeated stress.

Strength, Toughness & Durability

- TPU: High tensile strength and excellent tear resistance. Performs well even under sudden impact or continuous mechanical loading.

- TPE: Lower overall tensile strength; still durable but may be more prone to tearing under extreme strain.

If you need a material for load-bearing or high-impact applications, TPU is typically the better choice.

Abrasion & Wear Resistance

- TPU: Outstanding abrasion resistance—one of its strongest advantages.

- TPE: Good abrasion resistance but generally inferior to TPU.

This makes TPU the preferred material for caster wheels, protective covers, and mechanical components subjected to friction.

Chemical & Environmental Resistance

- TPU: Superior resistance to oils, greases, fuels, and many solvents.

- TPE: Moderate resistance; highly dependent on specific formulation.

For industrial parts or components exposed to harsh environments, TPU provides better long-term performance.

4. Printability Comparison

While mechanical properties are important, printability often becomes the deciding factor—especially for hobbyists and small workshops.

Here’s how TPU and TPE differ on the printer.

Extruder Compatibility

TPU

- Prints well on both direct drive and Bowden extruders

- Semi-rigid enough to feed reliably

- Good choice for printers not specifically optimized for flexible materials

TPE

- Typically requires a direct drive extruder

- Softer materials tend to compress and jam in Bowden tubes

- Feeds less easily due to a more rubber-like consistency

If your printer uses a Bowden setup, TPU is usually a safer and more frustration-free option.

Bed Adhesion

TPU

- Generally excellent adhesion

- Usually adheres to glass, PEI, and textured sheets without issues

TPE

- Can be trickier

- Some blends may require glue stick, tape, or specialized surfaces

- Prone to corner lifting on larger prints

Stringing and Oozing Behavior

Both TPU and TPE tend to string, but TPE is more challenging.

- TPU: Manageable with proper retraction settings

- TPE: Extremely prone to stringing; retraction often needs to be minimized to prevent jams

Print Speed Considerations

- TPU: Typically prints at 20–40 mm/s

- TPE: Often limited to 10–20 mm/s, especially with very soft formulations

Slower speeds mean longer print times, which may matter for production-scale use.

Dimensional Accuracy

- TPU: Retains shape well, good dimensional stability

- TPE: Softer mixtures may sag or deform, reducing dimensional accuracy

This makes TPU a better choice for components requiring tight tolerances or mechanical interfaces.

5. Application-Specific Insights

Best Uses for TPU

TPU is favored for parts requiring a balance of flexibility, toughness, and precision. Common applications include:

- Phone cases

- Protective covers

- Automotive gaskets and bushings

- Mechanical hinges or flexures

- Wearables requiring durability

- Vibration-dampening components

- Air ducts and CNC dust boots

- Sporting goods and protective gear

Its combination of durability and abrasion resistance makes it ideal for long-term, functional use.

Best Uses for TPE

TPE excels when softness, elasticity, and comfort matter most. Ideal applications include:

- Soft-touch grips

- Handle coatings

- Skin-contact products

- Straps and bands

- Seals requiring high compressibility

- Toys and consumer goods

- Overmolded components

Because TPE behaves more like traditional rubber, it’s a natural choice for ergonomic and comfort-driven products.

Overmolding and Multi-Material Printing

TPU and TPE can both be used in multi-material 3D printing to create dual-hardness parts. However:

- TPU bonds more reliably to rigid plastics such as PETG or PLA.

- TPE’s bonding depends heavily on formulation and may require specific pairings.

For multi-material assemblies, TPU again offers more predictable results.

6. Choosing the Right Shore Hardness

Shore hardness is a key specification for flexible filaments. It determines how soft or firm the printed part will feel.

TPU Typical Hardness

- 85A to 95A

- Flexible yet strong

- Suitable for functional mechanical parts

TPE Hardness Range

- As low as 70A

- Up to 90A

- Some extremely soft varieties feel like silicone

Rule of thumb:

- Higher Shore (95A) = firmer, less flexible

- Lower Shore (70A) = softer, more elastic

Choosing the right hardness depends on the tactile feel and functional stiffness you need.

7. Design Considerations for Flexible Filaments

Designing for flexibility requires a different mindset than designing for rigid plastics.

Wall Thickness

- Thicker walls increase stiffness

- Thinner walls enhance flexibility

Infill Patterns

- Gyroid and cubic infills improve resilience and cushioning

- Higher infill percentage increases firmness

Bridging and Overhangs

- Both TPU and TPE struggle with bridging

- Avoid unsupported overhangs where possible

Tolerance for Fitment

- TPU prints fit dimensionally accurate mechanical interfaces

- TPE may require slightly looser tolerances due to softness

Careful design ensures your flexible parts perform as intended.

8. Cost and Availability

TPU

- Widely available

- Price: typically mid-range

- Higher-end engineering TPU blends exist for industrial use

TPE

- Available in many formulations

- Cost varies significantly depending on softness and additives

- Ultra-soft blends tend to be more expensive

In most markets, TPU is easier to source consistently with predictable quality.

9. Which Should You Choose? A Scenario-Based Guide

Choose TPU if you need:

- High durability

- Consistent dimensional accuracy

- Good abrasion resistance

- Smooth, reliable printing

- Mechanical performance under stress

- Compatibility with Bowden printers

Choose TPE if you need:

- Soft-touch comfort

- Very high elasticity

- Skin-safe consumer products

- Soft, compressible components

- Overmolded grip-like applications

If you’re a beginner, TPU is usually the better choice.

TPE can be rewarding, but requires more tuning and experience.

10. FAQs About TPU vs. TPE

1. Is TPU more durable than TPE?

Yes. TPU generally provides superior durability, abrasion resistance, and toughness. TPE offers more softness but may not withstand heavy mechanical loads as well as TPU.

2. Which flexible filament is easier to print?

TPU is significantly easier to print than TPE, particularly on printers with Bowden extruders. TPE often requires a direct drive extruder and very slow speeds.

3. Can TPU be used for outdoor applications?

TPU performs well outdoors thanks to good UV stability, chemical resistance, and wear resistance. Some TPE blends are also suitable, but performance varies by formulation.

4. What Shore hardness is best for general flexible prints?

A Shore hardness around 95A is a good starting point for functional TPU prints, balancing flexibility and strength.

5. Can I print TPE on a Bowden extruder?

Not recommended. Soft TPE materials frequently compress inside the Bowden tube, causing jams or feeding issues. Direct drive systems handle TPE far better.

6. Which filament is better for phone cases?

Most phone cases are best printed in TPU because it offers a good blend of flexibility, impact resistance, and dimensional accuracy. TPE is suitable only for ultra-soft cases.

7. Does TPU or TPE bond better with other materials?

TPU bonds more predictably with common 3D printing polymers like PLA or PETG. TPE can bond well, but results vary significantly between formulations.

8. What is the difference in flexibility between TPU and TPE?

TPE generally feels softer and more rubber-like, with higher elasticity. TPU is flexible but tends to be firmer and more durable.

Conclusion: Which One Should You Choose?

Both TPU and TPE deliver the benefits of flexible materials, but they excel in different areas. TPU stands out as the more versatile, durable, and printer-friendly option, making it the top choice for functional, load-bearing, and high-precision applications. TPE, on the other hand, shines in comfort-oriented designs where softness and elasticity matter more than structural performance.

If you’re new to flexible filaments or printing functional parts, TPU is the ideal starting point.

If you’re creating soft-touch or ergonomic components, TPE may give you the tactile properties you need.

Choosing the right material ensures that your prints not only look correct but perform exactly as intended—whether they’re deployed in consumer products, prototypes, or industrial environments.